Day 3 :

Keynote Forum

Matjaz Kunaver

National institute of chemistry, Slovenia

Keynote: BIOMASS WASTE – A SOURCE OF RAW MATERIALS AND NANOCELLULOSE

Time : 10:00-10:30

Biography:

Matjaž Kunaver has done his MSc from the University of Leeds UK in 1991 and has received his PhD degree in 1998 at the University of Leeds, UK. He is a Senior Scientist Researcher at the National Institute of Chemistry, Laboratory for Polymer Chemistry and Technology, Ljubljana, Slovenia and is an Assistant Professor at the University of Ljubljana and Polymer Technology College. His main fields of research are the utilization of biomass as a feedstock for polymer synthesis and production of nanocellulose. He has published more than 50 original scientific papers and 6 patents.

Abstract:

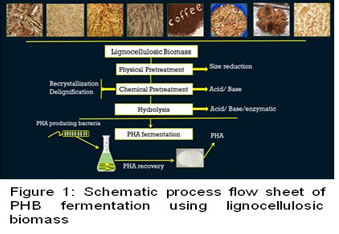

Cellulose containing Biomass represents an immense and renewable source for the production of bio-fuels and valuable chemicals. A little amount of this is used in industry and the remaining is leftover in huge quantities. Much effort has been devoted to converting these types of biomass into useful industrial and commercially viable products. In recent years, some effective processes have been found, such as thermochemical conversion producing several new products from these renewable resources. An overview of such applications and methods will be presented in this contribution. One of possibilities of converting biomass is the liquefactioni]. During liquefaction reaction, lignocellulosic components are depolymerised to low molecular mass compounds with high reactivity, high hydroxyl group content and can be used in many useful applications. A high energy ultrasound or microwaves can be used as an energy source to speed up the liquefaction process. The liquefied biomass was used as a feedstock in the synthesis of polyesters, polyurethane foams and adhesives. The same liquefaction process was used for the isolation of the nanocrystalline cellulose from biomass. The method is a novelty and a

model procedure for NCC isolation from different natural cellulosic sources with high yields and with high crystallinity index[i].

The process of preparing NCC from different natural sources uses glycols as the main reactant and an acid catalyst in low concentration (only 3%). Here, during the one step reaction, lignin, hemicelluloses and the more disordered components of the cellulosic fibers are liquefied, only the crystalline cellulose remaining as a solid residue.

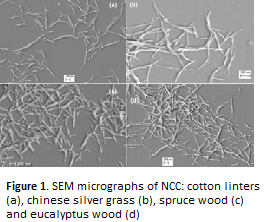

The liquefaction reaction, using glycols and mild acid catalysis, was optimized and applied to four model materials, namely cotton linters, spruce wood, eucalyptus wood and Chinese switch grass. The % recovery of the nanocrystalline cellulose, the crystallinity index of the nanocrystalline cellulose and the average crystal dimensions are presented in the Table 1. The main benefit of the process arises from the ability to prepare stable NCC suspensions in an organic medium at 10 times greater loadings than can be achieved in aqueous suspensions. The liquid residues contain significant quantities of levulinic acid and different sugars that were derived from cellulose and hemicelluloses.

Keynote Forum

Maximilian Lackner

University of Applied Sciences FH Technikum Wien, Austria

Keynote: Cyanobacteria as model organism for PHB production

Time : 10:30-11:00

Biography:

Dr. Maximilian Lackner earned his PhD in 2003 and his habilitation in 2009 from Vienna University of Technology. He has held several senior leadership positions in the polymer industry in Austria and China. Dr. Lackner has founded 5 companies, amongst them one for antimicrobial polymers and one in the area of bioplastics, Lackner Ventures & Consulting GmbH. The company collaborates with JinHui Zhaolong, one of the largest PBAT manufacturers. The research interests of Dr. Lackner include PHA and PBAT for PP and PE replacement, respectively. Lackner Ventures & Consulting GmbH runs a research project to produce PHB from CO2 and sunlight using cyanobacteria. Dr. Lackner has authored more than 100 scientific articles, a textbook and has edited several reference works, e.g. Springer’s “Handbook of Climate Change Mitigation and Adaptation” (2nd edition). He teaches materials science at the University of Applied Sciences FH Technikum Wien.

Abstract:

The increasing effect of non-degradable plastic wastes is a growing concern. Polyhydroxybutyrate (PHB) is a storage compound and the raw material for biodegradable plastics with properties comparable to PP. PHB can be completely mineralized into water and carbon dioxide by naturally occurring microorganisms. It is also a biocompatible material and is being studied for its application in biomedical and biopharmaceutical field as biodegradable drug delivery system as it is compatible with mammalian blood and tissue. Currently, PHAs are solely synthesized by heterotrophic bacteria using sugar fermentation. The relatively high costs of raw materials and continuous oxygen supply for the processing make PHAs expensive in comparison to other petroleum-derived plastics. Methodology and theory: The alternative is to use certain oxygenic cyanobacteria as cell factory. Cyanobacteria can store PHB under nutrient (P, N) limitation from renewable and sustainable resources sunlight and CO2 and due to their minimal nutrient requirement are the most promising host system for PHB production. However the growth rate and the PHB yield stay low. There exists no general method to increase PHB yield in cyanobacteria. This work aims at making cyanobacteria competitive by optimization of growth conditions and by strain selection. Findings: We screen for wild type strains which can naturally accumulate PHB. During our systematic screening we have discovered a cyanobacterium sp. strain which naturally accumulates a high PHB content under N and P limitations in comparison to other existing strains. The improvement of the strain is possible using process engineering and natural mutations. Significance: Our project can develop an economically superior bioprocess to enhance biomass growth and PHB productivity and prove feasibility to use CO2 for production of biodegradable plastics.

Networking & Refreshment Break 11:00-11:20 @ Foyer

- Biopolymer Applications | Advanced Biopolymers | Biopolymers for Tissue Engineering and Regenerative medicine

Session Introduction

Anand Gadre

University of California, Merced, USA

Title: Advanced bioplymeric electrospun nanoscale fibers for controlled drug delivery

Time : 11:50-12:15

Biography:

Anand Gadre graduated with his BS in Applied Physics from the University of Mumbai, MS Degree at the Institute of Science, Mumbai and his doctorate (Ph.D.) from the Institute of Chemical Technology (ICT), Mumbai, (India). Anand joined University of Maryland (USA) as a Postdoctoral Research Associate and further continued working in Georgetown University at Washington DC. Anand was then appointed as an Assistant Professor of Nanobioscience at the College of Nanoscale Science and Engineering in the State University of New York at Albany and later was promoted as an Associate Professor of Nanobioscience with tenure. While working at CNSE, Anand also achieved his Master in Business Management (MBA) degree from the State University of New York at Albany. Since 2011, Anand has been working as Director of the Stem Cell Instrumentation Foundry (SCIF) at the University of California, Merced where he is currently administering core research facilities and pursuing his research in the areas of Nanobiotechnology.

Abstract:

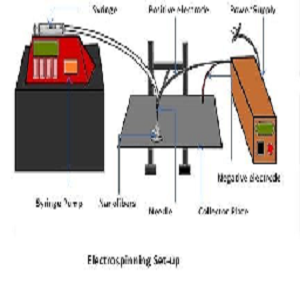

Advanced biocompatible polymers and co-polymers have been successfully implemented to generate electrospun nanofibers for variety of biological and biomedical applications. This work focused on generating a biopolymeric drug delivery system using (Poly-Lactic- co-Glycolic Acid (PLGA). Controlled drug elution targets a specific location to avoid overdosing and thereby reducing the side effects of the drug. In this study, we prepared a local anesthetic (Lidocaine) as well as an antibiotic (Chloramphenicol) loaded PLGA nanofibers using electrospinning technique and evaluated the drug release activity at a stable rate. Electrospinning is performed by applying a large positive voltage (several kV) to a metal syringe tip, which dispenses a polymer solution. The potential field draws a fiber from the end of the tip and deposits a randomly oriented and non- woven mat of polymeric fiber on a grounded metal collector plate. Depending on spinning parameters, fibers ranging from as small as 100 nm to as large as several micrometers can be achieved. We can alter the fiber diameter to control the rate of delivery. Fibers of lager diameter will have smaller surface area to volume ratios and should therefore release drug molecules compounds at a slower rate, but for a longer period of time. Conversely, smaller diameter fibers could release drug molecules at a faster rate, which could be beneficial for initial treatment.

Structural and optical properties of such drug loaded fibers confirmed the presence of drug molecules. Systematic drug elution experiments using UV- spectrophotometry were performed to observe possible indication in the absorbance change as the drug elutes from the nanofibers over the period of time. Drug loaded biopolymeric nanofibers also showed limited cytotoxicity on fibroblasts with viability greater than 96%. Such drug-loaded biopolymeric nanofibers can be applied via different routes, such as implantation, injection, and/or oral administration for a wide range of medical treatments.

Patrizia Cinelli

University of Pisa, Italy

Title: Sustainable Composites based on biopolymers and natural fibres

Time : 12:15-12:40

Biography:

Dr. Patrizia Cinelli PhD in Chemistry at Pisa University partly performed at the United States Department of Agriculture (USDA), Peoria, IL, USA. Over 20 years of experience in materials science, polymer processing and characterization, biodegradation and life cycle assessment. She is co-author of over 50 papers in peer-reviewed journal, 9 book chapters, and 8 patents on innovative materials. She is assistant professor of applied chemistry and Materials Technology at Master Degree student of Construction Engineering and Architecture at Pisa University. She has worked in over 15 EC project from FP5, FP6, FP7 and Horizon 2020, directly following technical management, proposal writing, scientific activity, and reporting

Abstract:

The utilization of “Bio-polymers” for production of bio-based composites has attracted interest of various application sectors ranging from packaging to automotive components and other high value applications.

Advantages of natural fibres are their lightweight, relative cheapness, being bio-based, and the fact that they can compete well with conventional reinforcements such as glass and aramid fibres for terms of strength per weight of material. The strength of the bond between fibres and matrix is substantial for the best mechanical performances of a composite. Many factors interacting with each other affect the complex process of the fibre/matrix adhesion, which be influenced by the chemical nature of the polymeric matrix, manufacturing methods, processing parameters, surface modification of the fibres or by additives like adhesion modifier agents. For production of composites with bio based biodegradable polymers, it is important to address fibres pre-treatment and/or to use compatibilizing agents. These approaches are reviewed in the present contribute with reference on specific researches carried on in our laboratories.

Recent Publications

- E. Bugnicourt, P. Cinelli, A. Lazzeri, V. Alvarez; (2014) Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging, Express Polymer Letters 8(11), 791-808.

- V.T. Phuong, V. Gigante, L. Aliotta, M. B. Coltelli, P. Cinelli, A. Lazzeri. (2017) in press, Reactively extruded ecocomposites based on poly(lactic acid)/bisphenol A polycarbonate blends reinforced with regenerated cellulose microfibers, Composite Science and Technology, CSTE 6603. 139, 127–137

- F. Cicogna, S Coiai, C. De Monte, R. Spiniello, S. Fiori, Francesca Braca, M. Franceschi, P. Cinelli, A. Lazzeri, S.M.K. fehri, W. Oberhauser, E. Passaglia, (2017, ) PLA plasticized with low molecular weight polyesters: structural, thermal and biodegradability features, Polymer International, DOI:10.1002/pi.5356

- M. Seggiani, P. Cinelli, N. Mallegni, E. Balestri, M. Puccini, S. Vitolo, C. Lardicci, A. Lazzeri. (2017), New bio-composites based on Polyhydroxyalkanoates and Posidonia oceanica fibres for application in marine environment, Materials. 10, 326; doi:10.3390/ma10040326

- L. Aliotta, P. Cinelli, M. B. Coltelli, M.C. Righetti, M. Gazzano, A. Lazzeri. (2017) in press, Effect of nucleating agents on crystallinity, and properties of Poly (lactic acid) (PLA), European Polymer Journal. https://doi.org/10.1016/j.eurpolymj.2017.04.041

Bernaerts Katrien

Maastricht University, Netherlands

Title: Increasing the solubility range of polyesters by tuning their microstructure with comonomers.

Time : 12:40-13:05

Biography:

Katrien Bernaerts, born in 1978 in Neerpelt (Belgium) graduated as a licentiate (master) in chemistry from Ghent University (Belgium) in 2000. From 2000 – 2005 she performed in PhD in polymer chemistry in the group of Prof. Du Prez at Ghent University (Belgium) on the synthesis and evaluation of stimuli (pH and temperature) responsive copolymer architectures by combination of different polymerization techniques. After PhD, Katrien spent 7 years in industry, doing research in the field of coatings and fibers. Since 2012, she started as assistant professor polymer chemistry at Maastricht University. Her main research interest is the synthesis of renewable, functional (co)polymers with a variety of architectures via different chemistries and the study of their structure-property relationships in several fields of application e.g. stimuli-responsive polymers, organic coatings, fibers, organic membranes, engineering plastics and biomedical applications.

Abstract:

ω-Pentadecalactone (PDL) is a biobased 16-membered macrolactone that can be derived from renewable resources. Its regular structure makes it highly crystalline and thus interesting as a biobased replacement for linear low density polyethylene. However, its solubility is very limited (chloroform) which hinders the use of PDL polymers in other applications requiring large solubility range. Copolymerization with a branched lactone is one way to reduce crystallinity because it is expected to disrupt the co-polyesters’ microstructure. Nevertheless, it has been shown that the microstructure of PDL-based co-polyesters varies depending on the comonomer structure. A block copolyester is obtained with branched lactones while a random structure is obtained with unsubstituted lactones of various size.

It was attempted to break the crystallinity of PDL-based copolyesters with a view of increasing their solubility range. Therefore, PDL was copolymerized with the branched and biobased δ-undecalactone (UDL), whose homopolymer is amorphous. In order to assess the microstructure (random or block-like), monomer distribution within the PDL-co-UDL polyesters was assessed by 13C NMR. It was observed that crystallinity of the copolyesters was decreased but not suppressed as measured by DSC, partially because they did not display a fully random monomer order. Hansen solubility parameter determination however showed that the solubility range of the copolyesters was improved compared to PDL homopolymers.

Recent Publications

- Bernaerts, K.; Mestrom, L.; De Wildeman, S., Biocatalysis toward New Biobased Building Blocks for Polymeric Materials. In Applied Biocatalysis: From Fundamental Science to Industrial Applications, Liese A, Hilterhaus L, Kettling U, Antranikian G, Eds.; Wiley-VCH, 2016; pp 464

- Delgove, M.A.F.; Luchies, J.; Wauters, I.; Deroover, G.G.P., De Wildeman, S.M.A., Increasing the solubility range of polyesters by tuning their microstructure with comonomers, Polymer Chemistry, DOI: 10.1039/c7py00976c

- Wróblewska, A.A.; Bernaerts, K.V.; De Wildeman S.M.A., Rigid, bio-based polyamides from galactaric acid derivatives with elevated glass transition temperatures and their characterization, Polymer 124 (2017) 252-262

- Wróblewska, A.A.; Lingier, S.; Noordijk, J.; Du Prez, F.E.; De Wildeman, S.M.A.; Bernaerts, K.V., Polyamides based on a partially bio-based spirodiamine, submitted

Group Photo @ Amphitheatre

Lunch Break 13:05-13:50 @ NCafé

Egle Conforto

Université de La Rochelle, France

Title: An optimized methodology to analyze biopolymer capsules by environmental scanning electron microscopy

Time : 13:50-14:15

Biography:

Egle Conforto, an Italian and Brazilian materials and biomaterials scientist, is specialized in Scanning and Transmission Electron Microscopy, which is the red wire of her career. She obtained her BSc degree in Physics and her MSc in Materials Science at Sao Paulo University in Brazil, and worked for 8 years in R&D using electron microscopy. Her PhD degree in materials for nanoelectronics applications was obtained at Ecole Polytechnique Fédérale de Lausanne, Switzerland, where she worked for 10 more years as head of new projects in biomaterials analyzed by Electron Microscopy. Since 2004 she is the Head of the Electron Microscopy Laboratory at University La Rochelle, being the responsible for its management and for research projects in corrosion and in hydrogen precipitation in Ti and Zr. She is also responsible for the supervisor of master and PhD research works, as well as for undergraduate, graduate and continuing education in electron microscopy

Abstract:

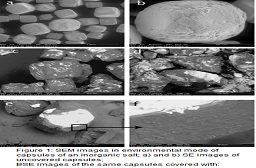

We propose an optimized methodology using Scanning Electron Microscopy (SEM) in environmental mode to study the surface characteristics and the internal structure of biopolymer capsules. Water vapor pressure in the 1.3 – 2.0 mbar range is introduced in the SEM specimen chamber during analyses to improve the electrical and thermal conductivity of the capsule surface, and to preserve it from damage. The main advantage of this methodology is that no preparation is required and, significantly, no metallic coverage is deposited on the surface of the specimen, thus preserving its original morphology. In particular, it avoids introducing preparation artefacts which could modify the capsule surface and shape, and mask information concerning important feature like porosities, roughness, coating continuity and cracks. Furthermore, chemical contrast is preserved in Backscattered Electron (BSE) images of unprepared samples, allowing visualizing the internal organization of the capsule, the quality of the envelope etc… Figures 1a and b show the surface morphology of uncovered capsules constituted of an inorganic salt by secondary electrons (SE) images. In Figure 1c and d, BSE images of the same salt coated by 10% of type A gelatin allows evaluating the coating permeability and the coating-core interactions. This information is also obtained from Figs. 1e and f where capsules of the same salt were covered by hydrogenated vegetable oil. We can observe fine details of gelatin and mainly fatty coatings, which are difficult to be analyzed by standard SEM techniques. For some simple fatty molecules like stearic acids for instance, environmental Energy Dispersive Spectroscopy (EDS) analyses have been successfully performed to obtain the relative concentration C/O. Finally, this methodology provides a reliable evaluation of the parameters used in capsule elaboration for research and industrial applications, as well as that of capsule functionality which is essential for the technological progress in this domain.

- Bugra O (2012) Complex coarcervation of collagen hydrolysates extracted from leather solid wastes and chitosan for controlled release of lavender oil, J. Environ. Manag. 100: 22–28.

- Paques JP, van der Linden E, van Rijn CJM, Sagis LMC (2013) Alginate submicron beads prepared through w/o emulsification and gelation with CaCl2 nanoparticles, Food Hydrocoll. 31:428–434.

- Rangrong Y, Suwabun C (2010) Encapsulation of ascobrylpalmitate in chitosan nanoparticles by oil-in-water emulsion and ionic gelation processes, Colloids Surf. B Biointerfaces 76:292–297.

- James B (2009) Advances in “wet” electronmicroscopy techniques and their application to the study of food structure, Trend Food Sci. Technol. 20:114–124.

- Muscariello L, Rosso F, Marino G, Giordano A, Barbarisi M, Cafiero G, Barbarisi A (2005) A critical overview of ESEM applications in the biological field, J. Cell. Physiol. 205:328–334.

Christine Jerome

University of Liège, Belgium

Title: Chitosan, a promising biomaterial for tissue engineering

Time : 14:15-14:40

Biography:

Christine Jérôme, full Professor at the University of Liege, has expertise in polymer chemistry and passion in developing biomaterials to improve health and well-being. She developed green strategies for the synthesis, functionalization and processing of polymer materials, degradable or not, to precisely tailor their properties and design supramolecular structures customised to the targeted biomedical application and needs.

Abstract:

Polymer hydrogels resemble the natural living tissue due to their high water content and soft consistency. They find many applications in the design and production of contact and intraocular lenses, biosensors membranes, matrices for repairing and regenerating a wide diversity of tissues and organs. Derived from chitin, chitosan is a unique biopolymer that exhibits outstanding properties, beside biocompatibility and biodegradability. Most of these peculiar properties arise from the presence of primary amines along the chitosan backbone. As a consequence, chitosan based hydrogels have shown a great potential for biomedical and pharmaceutical applications. Being degraded in a physiological environment into non-toxic products, chitosan is an outstanding candidate for short- to medium-term applications, such as tissue engineering. In this respect, the preparation of chitosan nanometric fibers mats is highly interesting as such structure mimics the one of skin extracellular matrix. Chitosan nanofibers can be prepared by electrospinning but suffer from weak mechanical resistance if they are used as such. Therefore, strategies allowing to generate chitosan based nanofiber mats exhibiting a mechanical resistance strong enough to be easily handled while keeping the peculiar features of chitosan hydrogels favoring the interaction with cells and soft tissues to provide efficient tissue reconstruction are needed. Findings: (i) combination of electrospinning with the layer-by-layer deposition [2-4] of chitosan, (ii) chemical cross-linking [5-6] of chitosan electropsun nanofibers and (iii) combination of chitosan/poly-caprolactone electrospun multilayers are three strategies that revealed to be efficient to improve the mechanical properties of chitosan nanofiber mats while preserving their biological properties. Conclusion and significance: the control of the nanofiber structure offered by the electrospinning technology makes the developed processes very promising to precisely design biomaterials for tissue engineering as demonstrated by preliminary cell culture tests corroborating the potential use of such systems in wound healing applications.

Recent Publications:

- Bugra O (2012) Complex coarcervation of collagen hydrolysates extracted from leather solid wastes and chitosan for controlled release of lavender oil, J. Environ. Manag. 100: 22–28.

- Paques JP, van der Linden E, van Rijn CJM, Sagis LMC (2013) Alginate submicron beads prepared through w/o emulsification and gelation with CaCl2 nanoparticles, Food Hydrocoll. 31:428–434.

- Rangrong Y, Suwabun C (2010) Encapsulation of ascobrylpalmitate in chitosan nanoparticles by oil-in-water emulsion and ionic gelation processes, Colloids Surf. B Biointerfaces 76:292–297.

- James B (2009) Advances in “wet” electronmicroscopy techniques and their application to the study of food structure, Trend Food Sci. Technol. 20:114–124.

- Muscariello L, Rosso F, Marino G, Giordano A, Barbarisi M, Cafiero G, Barbarisi A (2005) A critical overview of ESEM applications in the biological field, J. Cell. Physiol. 205:328–334.

Maia Merlani

Tbilisi State Medical University, Georgia

Title: New biopolymer from Comfrey: Chemistry and biological activity

Time : 14:40-15:05

Biography:

Maia Merlani has completed her PhD from Tbilisi State University. She is a Senior Research Scientist at Tbilisi State Medical University, department of plant biopolymers.. Her field of interest is a chemistry and synthesis of natural compounds. She is the author of more than 55 papers in reputed journals and presentations at 60 international scientific conferences. She was granted Georgian Presidential scholarship for young scientists (1997), NATO scholarship (2002, 2003-2006) and Matsumae International foundation scholarship (2013). She is a member of organizing committee of several international conferences in the field of organic and pharmaceutical Chemistry.

Abstract:

Comfrey root has been used as a traditional medicinal plant for the treatment of painful muscle and joint complaints for centuries. Recently biologically active polymer has been isolated from Caucasian species of comfrey Symphytum asperum Lepech. and S.caucasicum Bieb. This polymer - poly[3-(3,4-dihydroxyphenyl)glyceric acid] (p-DGA) is a representative of a new class of natural polyethers with a residue of 3-(3,4-dihydroxyphenyl)-glyceric acid (DGA) as the repeating unit. P-DGA exhibits high antioxidant, antiimfllamatory, wound healing and anticancer activities. In order to compare biological properties of natural polymer with its synthetic analogues, racemic and pure enantiomeric forms of DGA as well as a methylated analogue of p-DGA - poly(MCDMPO) as a precursor of p-DGA were synthesized. The racemic monomer and its virtually pure enantiomers were synthesized via Sharpless asymmetric dihydroxylation of trans-caffeic acid derivatives using an potassium osmiate catalyst, a stoichiometric oxidant N-methylmorpholine-N-oxide and enantiocomplementary catalysts cinchona alkaloid derivatives (DHQ)2-PHAL and (DHQD)2-PHA as chiral auxiliaries. Poly(MCDMPO) was obtained via ring opening polymerization of 2-methoxycarbonyl-3-(3,4-dimethoxyphenyl)-oxirane (MCDMPO) using a cationic initiator.

Comparative investigation of antioxidant properties of natural polymer and its monomer revealed that the latter appeared 40 fold active than polymer, however anticancer efficacy of p-DGA against human prostate cancer (PCA) cells is more compared to its synthetic monomer. Poly(MCDMPO) did not show any activity against PCA.

Recent Publications

- M. Merlani, Y. Koyama, H. Sato, L. Geng, V. Barbakadze, B. Chankvetadze, T. Nakano (2015) Ring-opening polymerization of a 2,3-disubstituted oxirane leading to a polyether having a carbonyl–aromatic π-stacked structure. Polym. Chem. 6:1932-1936.

- D.Tedesco, E.Fabini, V.Barbakadze, M.Merlani, R.Zanasi, B.Chankvetadze, C.Bertucci (2015) Stopped-Flow Enantioselective HPLC-CD Analysis and TD-DFT Stereochemical Characterization of Methyl Trans-3-(3,4-Dimethoxyphenyl)Glycidate. Chirality 27:12:914-918

- K.Lomsadze, M.Merlani, V.Barbakadze, T. Farkas, B. Chankvetadze (2012) Enantioseparation of Chiral Epoxides with Polysaccharide-Based Chiral Columns in HPLC. Chromatographia 75:.839–845.

- S.Shrotriya, G.Deep, K.Ramasamy, K.Raina, V. Barbakadze, M. Merlani, L. Gogilashvili, L. Amiranashvili,K. Mulkijanyan, K. Papadopoulos, Ch. Agarwal, R. Agarwal (2012) Poly[3-(3, 4-dihydroxyphenyl) glyceric acid] from Comfrey exerts anti-cancer efficacy against human prostate cancer via targeting androgen receptor, cell cycle arrest and apoptosis. Carcinogenesis 33:8:1572–1580

- M.Merlani, V.Barbakadze, L.Amiranashvili, L.Gogilashvili, E.Yannakopoulou, K.Papadopoulos, B.Chankvetadze (2010) Enantioselective synthesis and antioxidant activity of 3-(3,4-dihydroxyphenyl)-glyceric acid - Basic monomeric moiety of a biologically active polyether from Symphytum asperum and S. caucasicum Chirality 22: 8: 717-725.

Isabel Orlando

University of Westminster, UK

Title: Drug-free hydrogel based antibacterial hybrid polymers for wound healing applications

Time : 15:05-15:25

Biography:

Abstract:

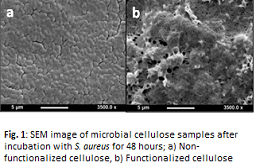

The unique mechanical and structural features of microbial cellulose (MC) make this polymer a promising starting material for applications in wound dressing and skin regeneration.1,2 MC presents a higher degree of crystallinity compared to plant cellulose, which results in better mechanical properties such as higher tensile strength and Young’s modulus. Moreover, the hydrogel-like structure enables MC to incorporate up to more than 90% its weight of water, ensuring an optimal level of moisture where applied.3 However, limitations to its use are related to the lack of antibacterial properties. Bacterial infections represent one of the major issues of concern for modern medicine because of the increasing resistance of bacteria against the traditional treatments.4,5 In this context, the need of novel strategies has become critical. HyMedPoly is a European project involving academic, industrial and clinical partners with an intent to generate a novel class of drug-free antibacterial materials based on natural and synthetic polymers as well as inorganic substrates. The focus of the research carried out at University of Westminster is to develop bacterial polymers with antibacterial properties for biomedical applications. In particular, this study aims to produce and chemically modify bacterial cellulose to obtain intrinsically active materials for wound dressing applications. A simple one-step reaction was performed to achieve the functionalization of the cellulose. The modified material was characterized using solid-state techniques such as Energy-dispersive X-ray Spectroscopy (EDX) and Fourier-Transformed Infra-Red (FT-IR). The activity of the antibacterial groups was evaluated by studying the inhibitory effect against Gram positive bacteria Staphylococcus aureus. Scanning electron microscopy (SEM) performed on modified MC samples after incubation with the bacteria showed a cell lysis based antibacterial activity (Fig. 1). Biocompatibility was assessed by testing the indirect cytotoxicity and the direct biocompatibility of the functionalised material using the HaCat cell line, a human keratinocyte cell line

Recent Publications

1. Kucińska-Lipka, J., Gubanska, I. and Janik, H., 2015. Bacterial cellulose in the field of wound healing and regenerative medicine of skin: recent trends and future prospectives. Polymer Bulletin, 72(9), pp.2399-2419.

2. Fu, L., Zhang, J. and Yang, G., 2013. Present status and applications of bacterial cellulose-based materials for skin tissue repair. Carbohydrate polymers, 92(2), pp.1432-1442.

3. Huang, Y., Zhu, C., Yang, J., Nie, Y., Chen, C. and Sun, D., 2014. Recent advances in bacterial cellulose. Cellulose, 21(1), pp.1-30.

4. Walsh, C., 2000. Molecular mechanisms that confer antibacterial drug resistance. Nature, 406(6797), pp.775-781.

5. Stewart, P.S. and Costerton, J.W., 2001. Antibiotic resistance of bacteria in biofilms. The Lancet, 358(9276), pp.135-138.

Hao Bai

Karlsruhe Institute of Technology (KIT), Germany

Title: UV-curable printed phosphorus-polymer thin film

Time : 15:25-15:45

Biography:

Hao Bai is a fresh PhD student who has his expertise in optical spectroscopy and developing optical sensor systems for online quality control of printed polymers. He works currently at Light Technology Institute in Karlsruhe, Germany. His main research topics relate to optical characterization of polymer thin films, imaging and laser spectroscopy based monitoring system development for the UV curing process. The current research project is financed by German Federal Ministry of Education and Research.

Abstract:

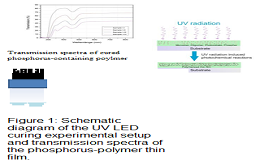

UV-radiation curing with photoinitiator and resins is used in variable industrial coating application. We develop a low-cost coating system through acylate polymer doped with luminescent pigment and UV curing process for white LED manufacturing. We printed the curable phosphor thin film doped with specialized acrylate coating formulation on fused silica glass substrate using spray coating and UV curing process. A homemade UV LED curing system with a wavelength of 365 nm is developed for coating process. This UV LED curing system has less energy consumption and environmentally friendly comparing with conventional gas-discharged lamp based curing system. Aluminium reflectors are integrated with the curing setup, which increased the total radiant energy flux. The glass substrate covered with unpolymerized resin layer is fixed on the top of the planer reflector during the curing process. Even low level of UV exposure (irradiance<0.5 W/cm²) is sufficient for complete polymerization. The surface profile of cured thin film shows ultra-high homogeneity and low root mean square value. The transmittance of the cured thin film adapts to the luminescence properties of white LED.

Oliver Meldrum

University of Queensland, Australia

Title: Hierarchical structure of mucin within the gastrointestinal tract and its interaction with dietary components

Time : 15:45-16:05

Biography:

Mr. Oliver Meldrum obtained a Bachelor of Science (Hons.) at the Australian National University and is currently undertaking a PhD at the University of Queensland. Oliver’s major research interest concern understanding the structure and rheology of mucus that lines the internal surfaces of the body and a focus on what food structure and food components are able to modify the physical and selective barrier properties of intestinal mucus.

Abstract:

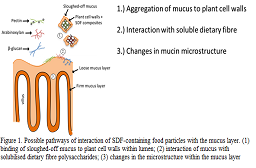

The adherent mucus layer is a vital component of the body’s epithelial surfaces. Mucus assembly is characterised by the presence of multiple levels of mucin structure at different length scales. This gives mucus its unique set of rheological and barrier properties that enable it to establish an effective physical and selective diffusion barrier as well as to hydrate the underlying epithelium. The rheological and structural characteristics of intestinal mucin, the functional component of the mucus layer and their interaction with cell wall components, that are liked with a number of health benefits are investigated. Biochemical well characterised porcine intestinal mucin has been utilised as a model for human mucins to characterise their viscoelasticity, structure and dynamics as a function of concentration, pH and Ca2+. The mesoscopic forces that mediate mucin were investigated using reducing, chaotropic and chelating agent agents. The rheological and structural characteristics of mucin were investigated using a combination of particle tracking microrheology, narrow gap oscillatory shear and high shear rheometry, and confocal microscopy. In this work, the complex rheological properties of the gelling mucus preparation are in a striking contrast with that of extensively purified mucin. The role and importance of non-mucin components have been elaborated, and the contribution to such interactions as hydrogen bonding, Ca2+-mediated links, and disulfide bonds has been evaluated. These bulk viscoelastic values are dominated by the elastic moduli, while the microrheological response is less dominant. We compare the ability of soluble dietary fibers and plant cell walls to alter the rheological and diffusion properties of purified intestinal mucin. Altering the organisation of mucus as a result of interactions with food components such as plant cell walls and soluble dietary fiber will provide new insights into the ways in which these nutritional components affect the barrier properties of mucus, and provide a possible underpinning mechanism contributing to their health promoting properties.

Recent publications

1. Lai SK, Wang Y-Y, Wirtz D, Hanes J. Micro- and macrorheology of mucus. Advanced Drug Delivery Reviews. 2009;61(2):86-100.

2. Linden SK, Sutton P, Karlsson NG, Korolik V, McGuckin MA. Mucins in the mucosal barrier to infection. Mucosal Immunol. 2008;1(3):183-97.

3. Georgiades P, Pudney PDA, Thornton DJ, Waigh TA. Particle Tracking Microrheology of Purified Gastrointestinal Mucins. Biopolymers. 2014;101(4):366-77.

4. Bansil R, Celli JP, Hardcastle JM, Turner BS. The Influence of Mucus Microstructure and Rheology in Helicobacter pylori Infection. Frontiers in immunology. 2013;4:310.

5. Bansil R, Turner BS. Mucin structure, aggregation, physiological functions and biomedical applications. Current Opinion in Colloid & Interface Science. 2006;11(2–3):164-70.

Networking & Refreshment Break 16:05-16:25 @ Foyer

Vakhtang Barbakadze

Tbilisi State Medical University, Georgia

Title: Novel biopolymer with anticancer activity

Biography:

Vakhtang Barbakadze has his expertise in isolation and structure elucidation of a new series of plant polyethers, which are endowed with pharmacological properties as anti- cancer agents. Besides, he interested in enantioselective synthesis and biological activities of basic monomeric moiety of these biopolyethers, synthesis of enantiomerically pure epoxides as chiral building blocks for the production of synthetic analogues of natural polyethers. In 1978 and 1999 he has completed his Ph.D and D.Sci. from Institute of Organic Chemistry, Moscow, Russia and Institute of Biochemistry and Biotechnology, Tbilisi, Georgia, respectively. 2006 up to date he is the head of laboratory of plant biopolymers at the Tbilisi State Medical University Institute of Pharmacochemistry. 1996 and 2002 he has been a visiting scientist at Utrecht University (faculty of pharmacy), The Netherlands, by University Scholarship and The Netherlands organization for scientific research Scholarship Scientific Program, respectively. He has published more than 81 papers in reputed journals.

Abstract:

Within the field of pharmacologically active biopolymers the area of stable polyethers seems rather new and attractive. Caffeic acid-derived polyethers are a class of natural products isolated from the root extracts of comfrey (Symphytum asperum) and bugloss (Anchusa italica). According to 13C, 1H NMR, 2D heteronuclear 1H/13C HSQC and 2D DOSY experiments the polyoxyethylene chain is the backbone of the polymer molecule. 3,4-Dihydroxyphenyl and carboxyl groups are regular substituents at two carbon atoms in the chain. The repeating unit of this regular polymer is 3-(3,4- dihydroxyphenyl)-glyceric acid residue. Thus, the structure of natural polymer under study was found to be poly[oxy-1-carboxy-2-(3,4- dihydroxyphenyl)ethylene] or poly[3-(3,4-dihydroxyphenyl)glyceric acid] (PDPGA). PDPGA is endowed with intriguing pharmacological properties as anticomplementary, antioxidant, anti-inflammatory, burn and wound healing and anticancer properties

We examined the efficacy of PDPGA of S.asperum (PDGPA- SA) and S.caucasicum (PDGPA-SC) in androgen-dependent (LNCaP) and independent (22Rv1 and PC3) human prostate cancer (PCA) cells. PDPGA-SA treatment (100 mcg/ml for 48h) decreases the live cell number by 65, 64 and 35% and increases the cell death by 16, 8 and 12 folds in LNCaP, 22Rv1 and PC3 cells, respectively. Similarly, PDPGA-SC treatment (100 mcg/ml for 48h) decreased the live cell number by 87, 25 and 33% and increased the cell death by 19, 10 and 9 folds in LNCaP, 22Rv1 and PC3 cells, respectively

PDPGA and its synthetic monomer exerted anti-cancer efficacy in vitro and in vivo against human prostate cancer (PCA) cells via targeting androgen receptor, cell cycle arrest and apoptosis without any toxicity, together with a strong decrease in prostate specific antigen level in plasma. However, our results showed that anticancer efficacy of PDPGA is more effective compared to its synthetic monomer. Overall, this study identifies PDPGA as a potent agent against PCA without any toxicity, and supports its clinical application

Henri Cramel

University of Bordeaux, France

Title: Glycolipids: from synthesis and self-assembly studies to the design of original bio-based polymers

Biography:

Henri Cramail completed his PhD from the LCPO at the University of Bordeaux 1, in 1990 and a post-doctoral stay at the University of Durham, U.K. Since 1999, he is full Professor of Polymer Chemistry at the University of Bordeaux. In 2004, he was awarded the position of Junior Member of the ‘Institut Universitaire de France’. He was the Director of the Laboratoire de Chimie des Polymères Organiques (LCPO) from 2007 to 2016 and he is today heading the ‘Biopolymers and bio-based polymers’ Team within LCPO. He has published more than 172 papers in reputed journals and, since 2016, is co-editor of the European Journal of Lipid Science and Technology

Abstract:

The aim of this work was to study glycolipids and particularly trehalose esters for the synthesis of new bio-sourced polymers. Trehalose monoesters and diesters were synthesized by two esterification pathways of the primary alcohol of trehalose with different fatty acids. The first synthetic route is a protective group-free esterification using a peptide coupling agent and the second one is a lipase-catalyzed esterification. The self-assembly properties of the trehalose esters were first investigated. While trehalose monoesters showed surfactant properties in water, trehalose diesters appeared to be good gelators for organic solvents and vegetable oils. In a second stage, trehalose diesters were functionalized and polymerized with different strategies. Thus, polyurethanes and poly(hydroxyurethane)s were obtained by polycondensation whereas glyco-polyesters were synthesized by acyclic diene metathesis (ADMET) and thiol-ene polymerizations. The self-assembly properties of these polymers were investigated; in some cases, the latter were able to form some nanoparticles by solvent displacement method.

Muhammad Mujtaba

Aksaray University, Turkey

Title: The present perspective and future of chitosan based bio-films

Biography:

Mr Muhammad Mujtaba is working on biopolymers in terms of its production, characterization and possible applications. On chitosan biofilm I am working since last year and I am trying to develop chitosan film with enhanced physicochemical properties such as high thermal stability, good mechanical properties etc. our group is dealing with cellulose, chitin and chitosan for its modification and applications

Abstract:

Nowadays researchers are showing great attention towards the natural polymer or biopolymer based materials such as chitin, chitosan and cellulose. Major reason after this growing interest are the desired properties possessed by such biopolymers including biodegradability, biocompatibility, nontoxicity, antimicrobial features. Production of chitosan based biofilms have been reported in many articles along with their possible applications in several fields such biomedical, food preservation etc. The modification of chitosan film depend upon the nature of application where they are supposed to be applied. Nowadays researcher are focusing more on the production chitosan active food packaging with good barrier, antioxidant and antimicrobial properties. These modification can be achieved by introducing certain active compounds such as plant extracts, essential oils and fruit extracts. Beside its application in food industry, chitosan films can be used as anti-biofilm drug carrier for wound healing where a prolonged release can be achieved. Keeping all these present applications in mind it can be concluded that still these chitosan films can be modified and enriched further for expanding its application areas. In the field of biomedical these films can be used as coating materials for all the appliances which are using in high temperature areas. This chitosan coating will help in protection of such valuable appliances due to its high thermal stability. But for such applications boosting of physicochemical properties is still needed. In future this can be achieved by incorporating several different compounds.

Biography:

Akbar Esmaeili has completed his Ph.D at the age of 47 years from Islamic Azad University, Tehran, Iran. He is the Prof. Department Chemical Engineering North Tehran Branch, Islamic Azad University. He has published more than 100 papers in reputed journals, more 13 books, referee for more 100 paper’s and serving as three editorial board member of repute

Abstract:

Abstract

The films based on methylcellulose with biodegradable and antioxidant activity incorporated with nano capsule suspension containing F. angulata essential oil were developed. Oil extraction and identification of F. angulata essential oil compounds was done. Nano capsule suspension containing F. angulata essential oil was prepared by ultrasonic bath. The films were prepared by a casting method in three different ratios. The mechanical properties, colour, light transmission, antioxidant activity and release rate characteristics of the films were studied. The addition of nano capsule suspension to methylcellulose films decreased the thickness, tensile strength but increased the percentage elongation at break (%E) and lightness. High antioxidant activity and a prolonged release of F. angulata essential oil were also reported. Five factors design of Response Surface Methodology were used to optimize the thickness, holding time and anti-oxidant effect of edible film based on methylcellulose incorporated with nano capsule suspension containing F. angulata essential oil. Design of experiments was carried out by the software: Minitab 17 (Sigma package). Optimization of thickness, 2, 2-diphenyl-1-picrylhydrazyl radical scavenging and holding time would yield the best mixture proportions of methylcellulose and nano capsule suspension 30%, 30% and 70%; oil.

- Bioplastics

Session Introduction

Ivana Marova

BUT, Czech Republic

Title: Application of PHA-based bioplastics in nanomaterials

Time : 16:25-16:50

Biography:

Ivana Marova works as Professor of Biochemistry at Faculty of Chemistry, Brno University of Technology in Brno (Czech Republic). Her scientific research is focused on microbial biotechnology, biochemistry, food chemistry and nanotechnology. After years of experience in research and teaching both in university and hospital institutions she with her collaborators has patented the biotechnological production PHA-based bioplastics on waste frying oil (PS3835CZ). This patent was licensed and, as HYDAL technology, circular and fully ecological biotechnology was awarded as the only Czech technology by “Frost and Sulliwan 2014 Technology Innovation Award”. At this time, the HYDAL technology is further developed by I Marova team. Low-end applications (folia; food package) as well as high-end applications (fibers, particles and 3D printed materials for biomedicine, pharmacy and cosmetics) are developed.

Abstract:

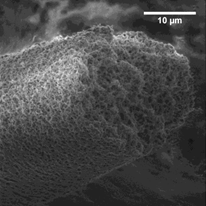

Natural polyesters, in particular, polyhydroxyalkanoates (PHA), can be regarded as some of the most promising polymers obtained from renewable sources suitable as drug carriers. They degrade completely without releasing toxic side products. The purpose of this work was to investigate the possibility for the preparation of functionalized PHA-based nanoparticles and PHA-fibrous materials containing natural extracts with antimicrobial effect. Biotechnologically produced PHA on waste frying oil (900 kDa) was used. Liposomes/PHB particles were used for encapsulation of water and oil plant extracts. Size and stability was determined using DLS. PHB nanofibers were prepared via three different techniques: electro-spinning, force-spinning and wet spinning. Using wet spinning patented technology unique microfibers with sub-micron structure containing nanopores and micropores structure in the whole cross section being of diameter 200 nm – 1 mm were obtained (Fig. 1). Particles and fibers (individually and in combined form) were functionalized with selected natural extracts and examined via SEM, FLIM and FTIR-ATR methods. For antioxidant activity and releasing of active substances spectrophotometric determination was used. Antimicrobial properties of prepared particles, extracts and fibers were examined using the bacterial and fungal test systems. Cytotoxicity of selected samples was tested with MTT assay. The performed microbiological screening and MTT cell viability studies revealed that predominantly cinnamon- and clove-containing nanofibrous materials were effective in suppressing the growth of the G+ bacteria Serratia marcescens and the G- bacteria Escherichia coli as well as yeast strain Candida glabrata. All PHA materials displayed good short- and long-term stability. No cytotoxicity against human keratinocytes was observed up to 8% of oil extracts. The obtained materials are promising for antibacterial and antifungal wound dressing applications as well as for local treatment in cosmetics.

Recent Publications

1. Rodriguez-Tobias H, Morales G, Ledezma A, Romero J, Saldívar J, Langlois V, Renard E, Grande D (2016) Electrospinning and electrospraying techniques for designing novel antibacterial poly(3-hydroxybutyrate)/zinc oxide nanofibrous composites Journal of Material Sciences 51:8593-8609.

2. Marova I, Kundrat V., Pospisil L (2016) Polymer fibre and its preparation. Czech Patent CZ306448.

3. Ignatova MG; Malonova NE; RAshkov IB; Markova ND; Toshkova RA; Georgieva AK; Nikolova EB (2016) Poly(3-hydroxybutyrate)/ caffeic acid electrospun fibrous materials coated with polyelectrolyte complex and their antibacterial activity and in vitro antitumor effect against HeLa cells. Materials Science and Engineering C 65: 379-392

4. Obruca S., Benesova P., Kucera D., Petrik S., Marova I. (2015): Biotechnological conversion of spent coffee grounds into polyhydroxyalkanoates and carotenoids. New Biotechnology 32 (6), Review. 569-574.

5. Matouskova P., Marova I., Bokrova J., Benesova P. (2016): Effect of Encapsulation on Antimicrobial Activity of Herbal Extracts with Lysozyme. Food Technology and Biotechnology 54(3), 304-316.

6. Obruca S, Sedlacek P, Krzyzanek V, Mravec F, Hrubanova K, Samek O, Kucera D, Benesova P, Marova, I (2016) Accumulation of Poly(3-hydroxybutyrate) Helps Bacterial Cells to Survive Freezing. PLOS ONE 11(6), 2016, DOI: 10.1371/journal.pone.0157778.

7. Obruca S., Sedlacek P, Mravec F, Samek O, Marova, I (2016) Evaluation of 3-hydroxybutyrate as an enzyme-protective agent against heating and oxidative damage and its potential role in stress response of poly(3-hydroxybutyrate) accumulating cells. Applied Microbiology and Biotechnology 100: 1365-1376.

Paolo Benincasa

University of Perugia, Italy

Title: Developing thermoplastic films from wheat flours with different proportions of finely grinded bran

Time : 16:50-17:15

Biography:

Paolo Benincasa is Associate Professor at the Dept. of Agricultural, Food and Environmental Sciences of the University of Perugia, Italy. He has 25-year expertise in Crop Science and Technology. His research activity focused on the evaluation of agronomic aspects affecting crop yield and quality and on the management of crop residues and soil fertility in conventional and organic farming systems. Recent research developed together with his colleagues of the Materials Engineering group focused on biobased materials, looking at the factors (cultivar, environment, cultivation practices, post-harvest manipulation) that may affect the mechanical properties of derived manufactures. Novel findings are reported in articles published in high ranked journals.

Abstract:

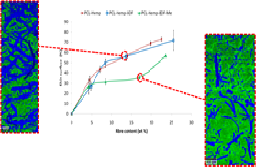

The use of wheat flour to obtain bioplastics has been proposed about one decade ago (1). Recent works from our group demonstrated that tensile properties of thermoplastic films depend on wheat grain hardness and baking properties of refined flours (2-3), expressed as Chopin’s alveograph parameters (P, L, P/L, W) (4). Moreover, we used wholegrain flours for producing bulk samples and found that the bran worked as a reinforcement, affecting tensile properties in function of the bran grinding level (5). This is of relevance being the bran a mill by-product to dispose of. This study was aimed at developing thermoplastic films from flours with different bran proportions.

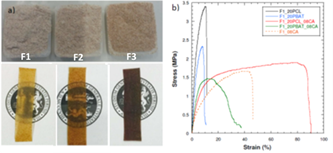

One refined wheat flour blend (F0, having P=64, L=99, P/L=0.65, W=182) from an industrial mill was mixed with three increasing proportions of finely grinded bran (treatments F1, F2 and F3, respectively). Roughly, F1 represented a wholegrain flour, F3 a grinding tail and F2 a mix 1:1 wt of F1 and F3. We tested several recipes and procedures, with progressive adjustments from that reported in Puglia et al. (2), and measured film tensile properties (strength, s; elongation at break, e) (2) (Figure 1).

By extruding the selected recipe (well defined proportions of wheat flour, glycerol, sorbitol, magnesium stearate, PVA/water solution) with a specific temperature profile (130-135-140°C), all flours gave films with s>2.0 MPa, while only F1 gave an acceptable e value. To further modulate e of films from F1, we investigated the blending with low melting biopolymers (PCL, PBAT) and plasticizer agents (citric acid). Results indicate that a 20-30% of PCL, plus citric acid, may give, even in presence of bran, a suitable deformation for crop mulching applications. All films were compostable and non-phytotoxic.

Results open perspectives for using wholegrain flours to obtain rigid and semi-rigid films, or deformable films suitable for mulching.

Figure 1: Wheat flours with different proportions of finely grinded bran and related thermoplastic extruded films (a) – tensile stress-strain curves for film containing low melting biopolymers (PCL, PBAT) and citric acid as plasticizer agent (b)

Recent Publications:

1. Leblanc N, Saiah R, Beucher E, Gattin R, Castandet M, Saiter J-M (2008). Structural investigation and thermal stability of new extruded wheat flour based polymeric materials. Carbohyd Polym 73: 548-557

2.Puglia D, Dominici F, Kenny JM, Santulli C, Governatori C, Tosti, G, Benincasa P (2016). Tensile behavior of thermoplastic films from wheat flours as function of raw material baking properties. J. Polym Environ 24: 37-47

3.Benincasa P, Dominici F, Bocci L, Governatori C, Panfili I, Tosti G, Torre L, Puglia D. Relationships between wheat flour baking properties and tensile characteristics of derived thermoplastic films. Ind Crops Prod, 100: 138-145.

4. Prabhasankar P, Sudha ML, Haridas Rao P (2000). Quality characteristics of wheat flour milled streams. Food Res Int 33: 381-386

5. Benincasa P, Puglia D, Dominici F (2017). Refining and bran grinding levels of wheat flours, besides baking properties, affect tensile characteristics of derived bioplastics. J Food Processing Technol 8:45

Huda S. Al-Battashi

Sultan Qaboos University, Oman

Title: Waste papers as a sustainable resource for the production of polyhydroxybutyrate (PHB) using Ralstonia eutropha ATCC 17699

Time : 17:15-17:35

Biography:

Huda Al-Battashi is a PhD student at Biology department, Sultan Qaboos University, Oman. She is working in biomass utilization for production of value added products. She did her BSc and MSc in College of Science, Sultan Qaboos University and graduated with Biotechnology major. She also has expertise in biopolymer production and chromium bioremediation

Abstract:

Polyhydroxybutyrae (PHB) is a biodegradable and biocompatible bioplastic that can replace conventional petroleum-derived plastics. The cost of PHB production is the major obstacle that hinders the production process and limiting their availability in the market compared with their petrochemical counterparts. In this work, PHB production was successfully implemented using waste papers, a cheap sustainable and renewable feedstock, as a raw material. The presence of 83% of carbohydrate in alkaline pretreated waste paper makes it a prospective source for bioplastic production. Alkaline-pretreatment (0.5% H2O2, 121°C, 30 min) of waste paper results in 91.93% glucose yield after enzymatic hydrolysis (37 FPU/g of cellulase and 50 CBU/g of β – glucosidase). Ralstonia eutropha ATCC 17699 was tested for its capability to produce poly-3-hydroxybutyrate (PHB) using waste paper hydrolysates as its sole carbon source in the deficiency of nitrogen source (20:1 C/N). Cells utilized the hydrolysate and accumulated 57 ± 1.83 % PHB of dry cell weight and produced 4.439 g PHB/l. The product yield coefficient was 0.3699 while 0.06 g/l/h volumetric productivity was achieved within 72 h of fermentation. Thus, waste paper hydrolysate is recommended as an excellent, cheap carbon substrate for PHB production.

Recent Publications

1. Huda S. AB, 3. Sivakumar, N., Saif A.B (2013) Screening of biopolymer producing bacteria isolated from some Brassica plants. 4th International Conference on Environmental Science and Development (ICESD2013), Dubai, 333-338

2. Huda S. AB., Sanket J., Bernhard P., Alyia A.A. (2016) The Geomicrobiology of Chromium (VI) Pollution: Microbial Diversity and its Bioremediation Potential. The Open Biotechnology Journal 10(Suppl-2, M10):379-389

Aleksandra A. Wroblewska

Maastricht University, New Zealand

Title: Beets to Biopolymers - Characterization of partially bio-based polyamides with elevated glass transition temperatures from rigid galactaric acid derivatives

Time : 17:35-17:55

Biography:

A main area of interest is the synthesis and characterization of biobased polyamides. In the past Aleksandra was working on the synthesis and modification of functionalized polyolefins at Sabic. Currently, Aleksandra became a PhD candidate in the newly formed group supervised by prof. Stefaan De Wildeman and dr. Katrien Bernaerts. Under their leadership she is synthesizing engineering plastics from biobased monomers. In this project, Maastricht University is part of the larger consortium “Beets to Biopolymers” with representatives of Cosun (NL), Philips (NL), Astron (NL) and Groningen University (NL). Together they aim at broadening the usage of biobased polymers in specialty applications. The effort made by the group from Maastricht University resulted in a couple of manuscripts which soon will be submitted to scientific journals

Abstract:

The focus of this research is the synthesis of amorphous polyamides from bio-based, cyclic monomers. Bio-based monomers are obtained from sugar beet pulp, as a side product in food industry. They are widely available and are gaining interest of researchers and industry through the last couple of decades. Their major disadvantage, which limits their wide spread utility, is the presence of different functional groups, which cause that those molecules are very often prone to degradation at elevated temperatures. On the other hand, their unique, rigid, cyclic structure contributes to better thermal properties of the product leading to more specialized applications for those polymers. Nonetheless, their incorporation into structure is challenging, mostly because of the elevated temperatures during the synthesis.

A comparative study was prepared investigating the synthesis of polyamides using bio-based building blocks, namely 2,3;4,5-(di-O-methylene)galactarate (GalXH) and 2,3;4,5-(di-O-isopropylidene)galactarate (GalXMe). Two different approaches towards the synthesis of biobased polyamides were tested: polycondensation in melt and polycondensation in solution via phosphorylation technique. The GalX monomers were combined with aliphatic, cycloaliphatic and aromatic diamines, resulting in amorphous polyamides with glass transition temperatures ranging from 50 °C – 220 °C. The obtained polyamides are stable at elevated temperatures above 300 °C. The polymerization of the GalXMe derivative results in polymer with narrow dispersities whereas GalXH gives polyamides with broad dispersities.

Recent Publications

1. Wroblewska, A.; Zych, A.; Thiyagarajan, S.; Dudenko, D.; van Es, D.; Hansen, M. R.; Koning, C.; Duchateau, R.; Jasinska- Walc, L., Towards sugar-derived polyamides as environmentally friendly materials. Polym. Chem. 2015, 6 (22), 4133-4143

Joseph K. Muiruri

National University of Singapore, Singapore

Title: Biodegradable and tough pla-cellulose based composites via stereo-complexation

Time : 17:55-18:15

Biography:

Joseph Kinyanjui Muiruri is currently a Ph.D student in Material Science and Engineering (MSE) at National University of Singapore (NUS) and Institute of Material Science and Engineering (IMRE). Joseph graduated with a Master’s degree from University of Nairobi, Kenya in 2011. He is a recipient of A*Star Singapore International Graduate Award (SINGA). He holds a Bachelor’s degree in Textile engineering from Moi University, Kenya. His research interests focuses on biopolymers and their nanocomposites for industrial applications

Abstract:

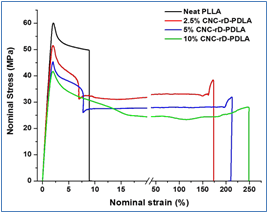

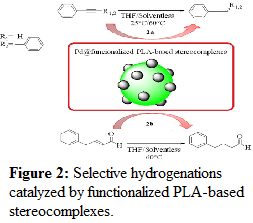

In recent years, sustainability and industrial ecology concerns have driven the search for alternatives to petrochemical based products to a whole new level [1]. As such biobased polymers have a competitive advantage, due to their eco-friendly properties. Among biobased polymers, poly (lactide) ( PLA) has been a frontrunner based on its good mechanical properties, coupled with its ‘green’ attributes. However, PLA is inherently brittle, slow in crystallization and low thermal stability. PLA, therefore, does not meet some market requirements for high end applications. Research has shown that these limitations are ‘improvable’ and PLA applications landscape widened by careful design of rigid-rubber matrix PLA modifiers [2-4]. In order to obtain a good matrix-filler interface adhesion, phase morphology at the interface can be tailored with the aid of stereocomplex crystallites [5].

In this work, Poly(L-lactide) cellulose nanocrystals-filled nanocomposites were fabricated by blending of cellulose nanocrystals-g-rubber-g-poly(D-lactide) (CNC-rD-PDLA) and commercial PLLA, in which CNC-g-rubber was synthesized by ring opening polymerization (ROP) of D-lactide and ε-caprolactone mixture to obtain CNC-P(CL-DLA), followed by further polymerization of D-lactide to obtain CNC-rD-PDLA. X-ray diffraction (XRD), nuclear magnetic resonance (NMR) and solubility tests confirmed successful grafting of the rubber segment and the PDLA segment onto CNC. Stereocomplexation between CNC-rD-PDLA nanofillers and PLLA matrix was confirmed by FT-IR, XRD and differential scanning calorimetry (DSC) characterization. The PLLA/CNC-rD-PDLA nanocomposites exhibited greatly improved tensile toughness. With 2.5% CNC-rD-PDLA loading, strain at break of PLLA/CNC-rD-PDLA was increased 20-fold, and the composite shows potential to replace poly (ethylene terephthalate). SEM and small angle x-ray scattering (SAXS) investigations revealed that fibrillation and crazing during deformation of PLLA/CNC-rD-PDLA nanocomposites were the major toughening mechanisms in this system. The highly biodegradable and tough cellulose nanocrystals-filled PLLA nanocomposites could tremendously widen the range of industrial applications of PLA

Recent Publications

1. Adams, W.M. The future of sustainability: Re-thinking environment and development in the twenty- first century. in Report of the IUCN renowned thinkers meeting. 2006.

2. He, C., et al., Composites, Nanocomposites and Hybrid Materials, in 50 Years of Materials Science in Singapore. 2016, World Scientific. p. 21-36.

3. Sun, Y. and C.B. He, Biodegradable "Core-Shell" Rubber Nanoparticles and Their Toughening of Poly(lactides). Macromolecules, 2013. 46(24): p. 9625-9633.

4. Sun, Y., et al., Biodegradable and renewable poly(lactide)-lignin composites: synthesis, interface and toughening mechanism. Journal of Materials Chemistry A, 2015. 3(7): p. 3699-3709.

5. Liu, Z., et al., Achieving a low electrical percolation threshold and superior mechanical performance in poly (L-lactide)/thermoplastic polyurethane/carbon nanotubes composites via tailoring phase morphology with the aid of stereocomplex crystallites. RSC Advances, 2017. 7(18): p. 11076-11084.

Yakubu Muntaka Musah

University of Professional Studies, Ghana

Title: How can Ghana attain petroleum based plastic to achieve a clean environment?

Time : 18:15-18:35

Biography:

Yakubu Musah Muntaka finished his school at St. Peters International School early 1999s and later finished junior high school at kings International School in 2004. He completed high school from Adventist High School. He then moved further to the University of Professional Studies, Accra where he pursued his degree in Business Administration and held various leadership position as the local NUGS President. A year after he worked at National Health Insurance Scheme (NHIS) as an Assistant Administrator and moved to Milito Enterprise Dworwulu as an administrator in May 2015. Two years after he established his own enterprise, YM Ventures which deals with import and export of general goods. Currently he is pursuing Masters Programme in Oil and Gas at the University of Professional Studies, Accra.Company.

Abstract:

Bioplastics are plastics in which all carbon is derived from renewable feedstock. The application of biomass such as starch, cellulose, wood and sugar used to substitute fossil resources for the production of plastics which is widely accepted strategy towards sustainable development. In this way, a significant reduction of carbon dioxide emission. It also helps in the reduction of global warming. Ghana is a country located in the west of Africa, relatively richer in oil and gas resources, and produces about 50,000 tons of plastic waste daily from industries, factories, and households. As a result, the house of parliament has conferred an institution to collect plastic waste for recycling and disposal, but the company do not have the technical capacity and machinery to convert the tonnes of plastic waste into bio plastics. Due to this development, Ghana was recently ranked as one of the dirtiest country in Africa because the mandated company fail to collect the tonnes of plastic waste due to lack of capacity. As an agricultural country, that has been the second largest producer of cocoa in the world, most of the produce are agriculture in nature and for that matter can easily be degraded within shortest possible time. From Ghana statistical service, the country loses about $1.25 million through indiscriminate disposal of plastic waste and this could prevent Ghana from meeting the sustainable development goals. In addition, Ghana uses about 5 million litres of petrol and diesel daily that has a significant effect on the environment and the health of the citizens. With the introduction of the bio plastics it would help Ghana to reduce the excessive emission of the carbon dioxide and reduce global warming as well. Since Ghana was ranked 5th in Africa that produces and uses polythene in Africa, and experts are of the view that Ghana would be able to easily convert its organic substances into bio plastics.

- Biopolymers as Materials | Green Composites in Biopolymers

Session Introduction

Takashi Yamashita

Tokyo University of Technology, Japan

Title: Development of Glycol-Lignin Derivatives for High Performance Hybrid Materials

Time : 11:20-11:45

Biography:

Professor Dr. Takashi Yamashita had been graduated from The University of Tokyo in 1984, then he had gotten Ph., D. from the University of Tokyo. He had worked for the University of Tokyo, Tokyo University of Science, and then he moved to Tokyo University of Technology in 2014 as the Department Head. His research interests cover development of photo-functional materials such as molecular machines, development of functional polyimides, development of the materials with nano-structure, fundamental theory on solid state photochemistry, and development of bio-mass materials. He had received Award of Photopolymer Science and Technology, and so on

Abstract:

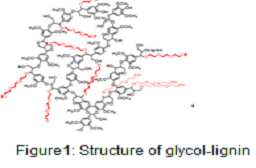

Lignin is one of the natural resources contained in coniferous trees up to 30% in weight, but it has not been utilized as a useful material up to now in contrast to the wide application of celluloses. Recently Dr. Yamada has invented “glycollignin”, which is soluble materials directly derived from coniferous tree chips by the solvolysis with oligo-ethylene glycol. We have developed hybrid film materials with the glycol-lignin and clays which have excellent properties such as insulation, gas barrier, surge resistance and so on as well as thermal stability, and which are now applied as gasket packings FRP matrices and so on. In order to improve the film properties and processability of the glycol lignin, we prepared several derivatives of the glycol-lignin. Phenolic hydroxyl groups and the hydroxyl groups of ethylene glycol chains on the glycol-lignin were determined as 1.89mmol/g and 2.35mmol/g, respectively based on the acetylation method. Then several functional groups such as diisocyanates, dianhydrids, chlorides, epoxides and so on were introduced on the active hydroxyl moieties to the materials. Introduction of (di)anhydrides afford the material water-solubility which improved the fabrication process so much. Addition of diisocianates gave water-containing-elastic gelly materials. Thus chemical modification of the glycol-lignin has opened a door to the wide application of the materials from the view point of sustainable engineering.

Recent Publications

1. K. Okano, S. Aya, F. Araoka, H. Obara, S. Sato, T. Yamashita, H. Takezoe, K. Asakura, Photoresponsive stripe patterns in achiral azobenzene liquid crystals, Chem Phys Chem., 16, 95–98 (2015).

2. T. Shima, T. Muraoka, T. Hamada, M. Morita, M. Takagi, H. Fukuoka, Y. Inoue, T. Sagawa, A. Ishijima, Y. Omata, T. Yamashita, K. Kinbara Micrometer-Size Vesicle Formation Triggered by UV Light, Langmuir, 30, 7289- 7295 (2014)

3. S. Hirata, K.Totani, T. Yamashita, C. Adachi, M. Vacha, Large reverse saturable absorption under weak continuous incoherent light, Nature Materials, 13, 938- 946 (2014)

4. S. Aya , H. Obara , D. Pociecha , F. Araoka , K. Okano, K. Ishikawa , E. Gorecka , T. Yamashita , H. Takezoe, Highly Elastic Liquid Crystals with a Sub-nanonewton Bending Elastic Constant Mediated by the ResidentMolecular Assemblies, Adv. Mater, 26, 1918-22 (2014)

5. S. Deshayes, H. Cabral, T. Ishii, Y. Miura, S. Kobayashi, T. Yamashita, A. Matsumoto, Y. Miyahara, N. Nishiyama, K. Kataoka, Phenylboronic Acid- Installed Polymeric Micelles for Targeting Sialylated Epitopes in Solid State Tumors J. Amer. Chem. Soc. 135 (41), 15501-15507 (2013)

Elisabete Frollini

University of Sao Paulo, Brazil

Title: Bio-based materials from renewable resources: A brief overview

Time : 11:45-12:10

Biography:

Elisabete Frollini is the Head of the Macromolecular Materials and Lignocellulosic Fiber Group, and is currently the coordinator of the Center for Research on Science and Technology of BioResources (Institute of Chemistry of Sao Carlos, University of Sao Paulo, Sao Carlos, Sao Paulo, Brazil). She has expertise in bio-based polymeric materials from biomass with an emphasis on lignocellulosic biomass, which has also been used within the scope of biorefinery.

Abstract:

Our research is focused on the use of raw materials which come from renewable sources and it aims at replacing those derived from petrochemical routes. In this context, cellulose derivatives have been synthesized for diversified applications1, polymers have been prepared for applications such as films, as well as matrices in composites reinforced with lignocellulosic fibers 2,3, which have also been used as reinforcement of biopolymers obtained on an industrial scale4. In addition, bio-based mats have been prepared from the electrospinning of solutions obtained from the dissolution of lignocellulosic fibers and/or from their main constituents, combined or not with other polymers5,6,. The methodologies used in these studies have followed what is described in the respective papers. Ongoing studies are conducted by using similar methodologies to those described in the papers already published2-6. Lignins and derivatives (such as lignosulfonates) have successfully replaced phenols in the synthesis of phenolic resins subsequently used as matrices in composites reinforced with lignocellulosic fibers (such as sugarcane bagasse, coconut, sisal, curauá), as well as polyol replacements in the synthesis of polyurethanes (combine or not with castor oil), which were later used as matrices and also as films. Recent studies, as well as those in progress, have shown that the properties of mats such as the diameters of ultrafine (submicron) and nanometric (diameter ≤ 100 nm) fibers, tensile properties, among others, can be tuned by the electrospinning of solutions obtained by the simultaneous dissolution of lignocellulosic fibers or the constituents thereof (cellulose and/or lignin) and a polymer, both when the fibers are randomly oriented and when they are preferably oriented in a certain direction. The set of results obtained in the mentioned studies, as well as in others not cited herein, has generally met the expectations and also matches the worldwide tendency to seek raw material from renewable sources that leads to products with good properties.

Recent Publications

1. Cerruti, BM, Zambon, MD, Megiatto Jr., JD, Frollini, E (2017) Synthesis of carboxymethylcelluloses with different degrees of substitution and their performance as renewable stabilizing agents for aqueous ceramic suspensions, Industrial Crops and Products, 107:54- 62.

2. De Oliveira F, Da Silva, C G, Ramos, Luiz A, Frollini, E. (2017) Phenolic and lignosulfonate-based matrices reinforced with untreated and lignosulfonate-treated sisal fibers, Industrial Crops and Products, 96:30-41.

3. Oliveira, FD., Ramires, EC., Frollini, E. (2015), Lignopolyurethanic materials based on oxypropylated sodium lignosulfonate and castor oil blends, Industrial Crops and Products 72:77-86.

4. Castro, DO, Passador, F, Ruvolo-Filho A, Frollini, E (2017) Use of castor and canola oils in “biopolyethylene” curauá fiber composites, Composites Part A-Applied Science and Manufacturing, 95:22-30.

5. Rodrigues, BVM, De Oliveira Santos, RP, Ramires, EC, Frollini, E (2015), Ultrathin and nanofibers via room temperature electrospinning from trifluoroacetic acid solutions of untreated lignocellulosic sisal fiber or sisal pulp, Journal of Applied Polymers Science, 132:1-8-

6. Santos, RPO Rodrigues, BVM, dos Santos, DM, Campana-Filho, SP., Ruvolo-Filho, AC, Frollini, E (2017) Electrospun recycled PET- based mats: Tuning the properties by addition of cellulose and/or lignin, Polymer Testing, 60:422-431.

12:10-12:40 Poster Presentations BP-01 to BP-10 @ Foyer

12:45-13:15 Poster Presentations BP-11 to BP-19 @ Foyer

Lunch Break 13:15-14:00 @ NCafé

Lovely Mathew

Viswajyothi College of Engineering and Technology, India

Title: Development of potentially biodegradable cellulose nanocrystal reinforced PBS-HBPP bionanocomposites

Time : 14:00-14:25

Biography:

Dr. Lovely Mathew has completed her Ph D from Cochin University of Science and Technology in 2006. She was the Professor of Chemistry Faculty in Newman College, Kerala since 1981. After her retirement in 2015, now she is working as a Professor and Project coordinator (Research) in Viswajyothi college of Engineering and Technology, Vazhakulam, Muvatupuzha, Kerala, India. She has published more than 20 papers in reputed international/national journals and has presented several research papers in various international conferences abroad. Her research area is natural fibre/nanocelluose reinforced polymer composites/Nanocomposites. She has completed several major research projects funded by DST, UGC KSCSTE, etc.. She is a registered guide of International and Inter University Centre for Nanoscience and Nanotechnology, Mahatma Gandhi University, Kottayam, Kerala ,India

Abstract:

A cost effective green approach has been used for the preparation of cellulose nanocrystals (CNC) from isora fibre which is a bast fibre obtained from the bark of Helicteres isora plant. The process involves microwave liquefaction followed by persulphate treatment. CNC’s were extensively characterized by SEM, TEM, AFM, TGA WAXRD etc; to establish the morphology, aspect ratio, crystallinity, thermal stability etc. The aim of this work is to study the property enhancement of Poly butyl succinate (PBS)- hyper branched polyester polyols (HBPP) blends by adding CNC’s at different proportions to give green composites with potential applications in areas such as food packaging and medicines. Biodegradable (PBS) / (HBPP) blended films were processed using a brabender twin-screw compounder machine. This paper reports a single step reactive extrusion process for the fabrication of thermally stable PBS-HBPP grafted CNC’s bio nanocomposite films using dicumyl peroxide as a cross linking agent. The effect of addition of CNC particles on the mechanical, thermal and barrier properties of PBS-HBPP blends were studied. Spherulitic morphology, chemical structure and crystalline structure of neat PBS and PBS-HBPP blended films were examined by optical polarizing microscopy (OPM), FTIR spectroscopy and WAXRD respectively.. The addition of HBPP increased the toughness, and wettability of the film. FTIR spectroscopy studies showed that the PBS-HBPP blend was grafted on CNC through a stable C- C bond formation. This strong chemical link led to the efficient transfer of modulus of CNC’s to the PBS-HBPP blend thereby increasing the tensile strength and young’s modulus to a greater extent. Significant reduction in water vapour and oxygen permeability rates was also observed for PBS-HBPP nanocomposite over neat PBS. Experimentally, it was observed that the CNC’s wt. content, size and morphology are the parameters that substantially influence the mechanical, thermal and barrier properties of the composite samples. The surface of the nano particles act as initiators for network formation, as observed by a scanning electron microscope (SEM) image of the fractured sample

Related Conferences

1. Kim H-S, Yang H-S, Kim H-J. Biodegradability and mechanical properties of agro-flour-filled polybutylene succinate biocomposites. J Appl Polym Sci 2005;97:1513–21.