Call for Abstract

Scientific Program

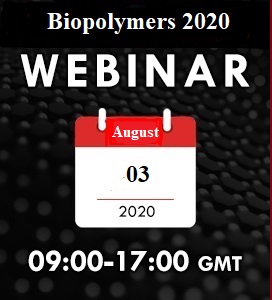

10th World Congress on Biopolymers & Bioplastics, will be organized around the theme “Solution for current & future global challenges Biopolymers 2020”

Biopolymers 2020 is comprised of keynote and speakers sessions on latest cutting edge research designed to offer comprehensive global discussions that address current issues in Biopolymers 2020

Submit your abstract to any of the mentioned tracks.

Register now for the conference by choosing an appropriate package suitable to you.

Biomaterials are those materials which have been engineered to interact with biological systems for used in basically medical purpose. to augment or replace a natural function. As a science, it’s been about fifty years old. Study of biomaterials is called biomaterials science or biomaterials engineering. Many companies investing huge amounts of money for the development of new products. It holds within elements of medicine, biology, chemistry, tissue engineering and materials science.

A Biocomposite is a composite material composed of matrix (resin) and a reinforcement of natural fibers. These kinds of materials always providing biocompatibility. The matrix phase is formed by polymers derived from renewable and non-renewable resources. The matrix is important to protect the fibers from environmental degradation and mechanical damage, to hold the fibers together and to transfer the loads on it.

- Track 1-1Biodegradable smart implants

- Track 1-2Polylactide (PLA) research

- Track 1-3Microbial cellulose for wound healing

- Track 1-4Natural and artificial chitosan

- Track 1-5Extracellular biopolymeric flocculants

- Track 1-6Porous chitosan-silica hybrid microspheres

- Track 1-7Lignin-containing polymer materials

- Track 1-8Nanocomposite hydrogels.

- Track 1-9Multiscale modelling of biodegradable polyesters

- Track 1-10Bio-inspired materials

- Track 1-11Polysaccharides food shelf-life extention

Polylactide (PLA) the most promising one of Biopolymers these are a type of plastics which is being manufactured from petrochemicals, generated from sustainable feed stocks such as sugar, starch or Cellulose. Till date, the use of biopolymers, includes the first generation PLA, has been limited by their Physical properties and relatively high cost to manufacture. Next generation biopolymers, are the Plastics component fabrication, Polysaccharides second generation PLA, are to be cheaper and to improve their performance and a wide variety of application to capture an increasing share of the various markets for Biopolymers. Innovations has already achieved significant success with its early investments its $1.5m investment in obesity drug developer return up to $22m, following its sale for $100m in 2013, while the sale of a small molecule drug discovery company, resulted in Innovations realizing $9.5m, a 4.7 return on investment. In year 2015, Innovations invested $14.0m in 20 ventures, helping to launch three new companies.

- Track 2-13D Printing of polymers and nanopolymer microstutures

- Track 2-2Additive Manufacture of polymeric materials

- Track 2-3Conductive Polymer Nanocomposites by Joule Heating

- Track 2-4Frontal polymerization technique for polymers and composites

- Track 2-5Chemistry of biopolymers

- Track 2-6Plastic component fabrication using Biopolymers

- Track 2-7Polylactic acid in Biopolymers

- Track 2-8Nucleic acids in Biopolymers

- Track 2-9Polysaccharides in Biopolymers

- Track 2-10Polynucleotide in Biopolymers

- Track 2-11Micro fabrication techniques

- Track 2-12Production of Biopolymers from Acetobacter xylinum

Bioplastics are plastics derived from renewable biomass sources, such as vegetable fats and oils, corn starch, or microbiota. Bioplastic can be made from agricultural by-products and also from used plastic bottles and other containers using microorganisms. Common plastics, such as fossil-fuel plastics are derived from petroleum or natural gas. Production of such plastics tends to require more fossil fuels and to produce more greenhouse gases than the production of biobased polymers (bioplastics). Some, but not all, bioplastics are designed to biodegrade. Biodegradable bioplastics can break down in either anaerobic or aerobic environments, depending on how they are manufactured. Bioplastics can be composed of starches, cellulose, biopolymers, and a variety of other materials.

- Track 3-1Nanotechnology for bioplastics

- Track 3-2Bioplastics: Applications in Medicine

- Track 3-3Health Care products with Bioplastics

- Track 3-4Thermoplastic and thermosetting Bioplastics

- Track 3-5BioBased Re-Invention of Plastics

- Track 3-6Polymer Brush Coated Colloids

- Track 3-7Bioplastics Engineering

- Track 3-8Food and Beverage Packaging Technology

- Track 3-9Bio-Based Plastics

- Track 3-10Synthetic Biology

- Track 3-11Innovations in Food Packaging

- Track 3-12Biodegradable Plastics

- Track 3-13Nanomaterials

Ocean plastic research is a relatively new field, the billions upon billions of items of plastic waste choking our oceans, lakes, and rivers and piling up on land is more than unsightly and harmful to plants and wildlife. About 8 million metric tons of plastic are thrown into the ocean annually. Of those, 236,000 tons are micro plastics– tiny pieces of broken-down plastic smaller than our little fingernail. There is more plastic than natural prey at the sea surface of the Great Pacific Garbage Patch, which means that organisms feeding at this area are likely to have plastic as a major component of their diets. For instance, sea turtles by-caught in fisheries operating within and around the patch can have up to 74% (by dry weight) of their diets composed of ocean plastics. By 2050 there will be more plastic in the oceans than there are fish (by weight).

- Track 4-1Biopolymers in Marine Sources

- Track 4-2Marine Plastic Pollution

- Track 4-3Plastic-free Ocean

Bioplastic packaging options include bags for compost, agricultural foils, horticultural products, nursery products, toys and textiles. They are also often used for disposable cups, salad bowls, plates, clingfilm and food containers. Bioplastics are used for disposable items, such as packaging, crockery, cutlery, pots, bowls, and straws.Few commercial applications exist for bioplastics. In principle they could replace many applications for petroleum-derived plastics, however cost and performance remain problematic. As a matter of fact, their usage is financially favourable only if supported by specific regulations limiting the usage of conventional plastics. Typical is the example of Italy, where biodegradable plastic bags and shoppers are compulsory since 2011 with the introduction of a specific law.Beyond structural materials, electroactive bioplastics are being developed that promise to be used to carry electric current.

- Track 5-1Nanotechnology for bioplastics

- Track 5-2Bioplastics: Applications in Medicine

- Track 5-3Health Care products with Bioplastics

Whole green composites are the composite materia Whole green composites are the composite materials that are made from both renewable resource based polymer (biopolymer) and ls that are made from both renewable resource based polymer (biopolymer) and bio-filler. Whole green composites are recyclable, renewable, triggered biodegradable and could reduce the dependency on the fossil fuel to a great extent when used in interior applications. Whole green composites could have major applications in automotive interiors, interior building applications and major packaging areas. Despite the large number of recent reviews on green composites defined as biopolymers or bio-derived polymers reinforced with natural fibers for bioprocessing of materials, limited investigation has taken place into the most appropriate applications for these materials. Global composite materials industry reached $19.6B in 2011, marking an annual increase of 8.2% from 2010 and driven by recovering of majority of markets. Market value of end use products made with composites was $55.6B in 2011. North American composites industry accelerated by 9 % in 2014, Europe increased by 8%while Asia grew by 7% in 2015. By 2017, composite materials industry is expected to reach $ 29.9B (7% CAGR) while end products made with composite materials market value is expected to reach $85B Global Automotive composite materials market was estimated to be around $ 2.8 B in 2015, and forecast to reach $ 4.3 B by 2017 @ CAGR of approx. 7%.

- Track 6-1Bio composites in Biopolymers

- Track 6-2Biopolymers usage in Bio Ceramics

- Track 6-3Biopolymers in Nanotechnology

- Track 6-4Polymer Physics

- Track 6-5Bionano Composites for Food packing applications of Biopolymers

- Track 6-6Micro & Nano Blends based on Natural polymers

- Track 6-7Wood & Wood polymer Composites in Biopolymers

- Track 6-8Green Plastics: An Introduction to the New Science of Biodegradable Plastics

Synthetic polymers are human-made polymers. They can be classified into four main categories: thermoplastics, thermosetting, elastomers, and synthetic fibers. They are commonly found in a variety of consumer products. synthetic polymers are used in home purpose and mainly in daily basic needs in house purpose. A wide variety of synthetic polymers are available with variations in main chain as well as side chains. The back bones of common synthetic polymers such as polythene, polystyrene and poly acrylates are made up of carbon-carbon bonds, whereas hetero chain polymers such as polyamides, polyesters, polyurethanes, polysulfides and polycarbonates have other elements (e.g. oxygen, sulfur, nitrogen) inserted along to the backbone. Also silicon forms similar materials without the need of carbon atoms, such as silicones through siloxane linkages; these compounds are thus said to be inorganic polymers. Coordination polymers may contain a range of metals in the backbone, with non-covalent bonding present.

- Track 7-1Thermoplastics polymers

- Track 7-2Thermosetting polymers

- Track 7-3Elastomers polymers

- Track 7-4low density polyethylene

- Track 7-5High density polyethylene

- Track 7-6Thermoplastic polyurethanes

- Track 7-7polyethylene terephthalate

- Track 7-8Biodegradeabl polymers

- Track 7-9Natural synthetic polymers

Organic polymers are macromolecules composed of many repeating monomer units. Both synthetic and natural polymers play a crucial role in everyday life. Polysaccharides, polypeptides, and polynucleotides are the main types of biopolymers in living cells. These polymers are synthesized by enzyme-mediated processes in cells. In general, synthetic polymers are derived from monomers that contain either a multiple bond, or two or more functional groups, or a three-to seven- membered ring.. The chemical properties of the polymers are derived from their monomer units, while the physical properties of polymers are different. Polymers, depending on their physical properties, are characterised as thermoplastics, thermo sets, elastomers and fibres.Organic polymers have wide variety of uses, for example: polystyrene resins are used in the production of home electronics and appliances; nylon-6 is used in textile and plastic industries. Organic polymers such as polyethylene terephthalate are in the manufacture of popular PET bottles. Others such as neoprene are used in shoe soles and wet suits, polyvinyl chloride in pipes and Teflon in non-stick pans.

- Track 8-1suspension polymerization

- Track 8-2clustering of ions

- Track 8-3crosslinking polymerization

- Track 8-4Porous organic polymers

- Track 8-5Ablation of organic polymers

- Track 8-6Fluorescent Microporous Organic Polymers

- Track 8-7Microporous organic polymers

- Track 8-8Synthesis of Luminescent Covalent–Organic Polymers

- Track 8-9Metal organic polymers

- Track 8-10Porphyrin based porous organic polymers

Linear polymers have a specific set of physicochemical and mechanical properties. The most important properties are the ability to form highstrength anisotropic, highly oriented fibers and films; the capacity for large, slowly developing reversibl deformations; the ability to swell in the hyperelastic state before dissolving; and the high viscosity of solutions. This set of properties results from the high molecular weight, the chain structure, and the flexibility of the macromolecules. In the transition from linear to branched, sparse threedimensional networks, and finally to dense cross linked structures, these properties become decreasingly pronounced. Strongly crosslinked polymers are insoluble, infusible, and incapable of hyperelastic deformations.

- Track 9-1super absorbent polymer

- Track 9-2condensation polymerization

- Track 9-3Molecularweight linear polymers

- Track 9-4Synthetic linear polymers

- Track 9-5Relaxation linear polymers

- Track 9-6Entangled linear polymers

- Track 9-7Viscoelastic properties linear polymers

- Track 9-8Single crystal linear polymers

- Track 9-9Microencapsulated linear polymer

- Track 9-10Doubly dendronized linear polymers

Thermosets and <a a="" about="" above="" ai-generated="" also="" and="" behave="" behavior="" best="" between="" by="" coarse="" coarsely="" compares="" completely="" cross-linked="" different="" elastic="" elastomer="" from="" glass="" has="" highly="" data-cke-saved-href="\" href="\" in="" is="" low="" mechanical="" moduli="" modulus="" more="" of="" plot="" polymers.="" reflected="" s="" shear="" temperature="" than="" the="" their="" thermoplastic="" title="\" learn"="" topic="" transition="" typical="" uncross-linked="" versus="">glass transition temperature. The glass transition temperature of these materials is usually below -50 °C, so they are soft and flexible at room temperature. In contrast, highly crosslinked systems, typical in thermosets, show a smaller decrease in stiffness as the material is raised above the glass transition temperature; the decrease in properties becomes smaller as the degree of cross-linking increases .crossed linked polymers are usually contains rubber in terms of flexibility. One of the most important properties of Cross-linked Polymers is that, they are thermosetting, which means, they cannot be melted or dissolved. So it can be harder for us to process this kind of polymer. They are considered as ideal dressings as they clean, rehydrate dry and necrotic tissues and initiate autolytic debridement. It has been reported that they promote moist healing and are used to treat venous leg ulcers.

- Track 10-1vulcanization polymerization

- Track 10-2step polymerization

- Track 10-3Ionic cross linking polymerization

- Track 10-4Recyclable crosslinked polymers

- Track 10-5Hydrogel synthesis crosslinking polymers

- Track 10-6Amorphous formation crosslink polymers

- Track 10-7Fluorocarbon crosslink polymers

- Track 10-8Thermally crosslink polymers

- Track 10-9Cellulose crosslink polymers

- Track 10-10.Post polymerization crosslink polymers

Amorphous polymers may exist in three physical states: vitreous, hyperelastic, and viscousflow. Polymers with a low temperature (below room temperature) for the transition from the vitreous to the hyperelastic state are called elastomers, and polymers with high transition temperatures are called plastics. The properties of polymers vary within a broad range, depending on chemical composition and the structure and mutual arrangement of the macromolecules. Thus 1,4cispolybutadiene, which is composed of flexible hydrocarbon chains, is elastic at about 20°C and undergoes transition to the vitreous state at 60°C. Polymethyl methacrylate, which is composed of more rigid chains, is a hard, vitreous substance at about 20°C and undergoes transition to the hyperelastic state only at 100°C. Cellulose, which is a polymer with very rigid chains linked by intermolecular hydrogen bonds, cannot exist at all in the hyperelastic state at temperatures below its decomposition point. Great differences may be seen in the properties of polymers even if the differences in the macromolecular structures are not great at first glance. Thus, stereoregular polystyrene is a crystalline substance with a melting point of about 235°C, whereas its nonstereoregular (atactic) analogue is completely incapable of crystallizing and softens at about 80°C.Amorphous polymers can exhibit a wide range of elastic properties depending upon the testing conditions (Young and Lovell 1991). At sufficiently low temperatures the polymer will be glassy with a modulus of the order of 3 GPa. As the test temperature is increased the modulus falls rapidly through the region of the glass transition temperature, Tg, where the polymer is viscoelastic and the modulus becomes very rate and temperature dependent. At a sufficiently high temperature the polymer becomes rubbery and if it is not cross-linked it will flow like a viscous liquid.

- Track 11-1Crystalline amorphous polymers

- Track 11-2Relaxation amorphous polymers

- Track 11-3Deformation amorphous polymers

- Track 11-4Orientation amorphous polymers

- Track 11-5Physical aging amorphous polymers

- Track 11-6Birefringence amorphous polymers

- Track 11-7Molecular dynamics amorphous polymers

- Track 11-8Solvent diffusion in amorphous polymers

- Track 11-9Novel kinetic model in amorphous polymers

- Track 11-10Physical gelation of amorphous polymers

Natural polymers include the RNA and DNA that are so important in genes and life processes. In fact, messenger RNA is what makes possible proteins, peptides, and enzymes. Enzymes help do the chemistry inside living organisms and peptides make up some of the more interesting structural components of skin, hair, and even the horns of rhinos. Other natural polymers include polysaccharides (sugar polymers), Cellulose, starch, lignin, chitin and polypeptides like silk, keratin, and hair. Natural rubber is, naturally a natural polymer also, made from just carbon and hydrogen. These materials and their derivatives offer a wide range of properties and applications. Natural polymers tend to be readily biodegradable, although the rate of degradation is generally inversely proportional to the extent of chemical modification. US companies demand for natural polymers is forecast to expand 6.9 % annually to $4.6 billion in 2016. Cellulose ethers, methyl cellulose, will remain the largest product segment. This study analyses the $3.3 billion US natural biopolymer industries. It presents historical demand data for the years 2001, 2006 and 2011, and forecasts for 2016 and 2021 by market.

- Track 12-1Polymer Gels usage in Biopolymers

- Track 12-2Rheology of Natural and Biopolymers

- Track 12-3Degradation & Stability approach through Biopolymers

- Track 12-4Chitin & Chitosan Polymers in Biopolymers

- Track 12-5Life cycle analysis of Biopolymers

- Track 12-6Natural polymeric vectors in Gene therapy

- Track 12-7Copolymers & Fibers

Polymer Nano composites (PNC) are made of a polymers or copolymers having nanoparticles or Nano fillers dispersed in the polymer matrix. The plastic used for food packaging and non-food applications is non-biodegradable, and also of valuable and scarce non-renewable resources like petroleum. With the current research on exploring the alternatives to petrol and priority on reduced environmental impact, research is increased in development of biodegradable packaging from biopolymer-based materials. A biomaterial is a surface, or construct that interacts with biological systems. These biomaterials are about fifty years old. The study of such materials is called biomaterials science. It has been seen a strong growth over its past period, were many companies have been investing large amounts in the development of new products. Biomaterials science is the elements of medicine, biology, chemistry, tissue engineering and materials science. The Biomaterial market over the forecast period of 2016-2021 market for biomaterials is likely to predict to USD 70.90 Billion in 2012 and is steady to grow at a CAGR of 16.0% from 2016 to 2021 to reach USD 149.17 Billion by 2021.

- Track 13-1Polymer hybrid assemblies

- Track 13-23D printing of materials in Biopolymers

- Track 13-3Surface and Interfaces of Biopolymers

- Track 13-4Industry and Market of Biopolymers

- Track 13-5Biopolymers for Food packaging

- Track 13-6Biopolymers for plastic production

- Track 13-7Biological materials in the areas of automotive manufacturing

Polymer processing is the technique of converting raw polymeric materials into completed products having desirable shape, microstructures and properties. The raw form of polymers is available initially as pellets which are heated to its glass transition temperature to form into a viscous fluid. The fluid is then subjected to moulding and rapid solidification by cooling which results in the development of the required shape and microstructures. This method has been a standard since for thermoplastic processing since the 1960s. Thermosetting plastics utilize a similar processing method but with additives and cross-linking agents. The crosslinking formed after cooling are and irreversible and re-heating will not be effective in liquefying the polymers.

Polymers modeling process has become prominent since the last decade, especially for processing soft materials. New sampling methods are developed to increase the exploration of configuration space, which has been still continues to be of paramount importance in the determining the properties of polymeric materials. The time duration and scaling issues are being addressed with new coarse-grained methods, while more traditional methods are being applied in increasing chemical complexity and reality.

- Track 14-1Biofilms

- Track 14-2Biopolymers for Drug delivery

- Track 14-3Nano medicines

- Track 14-4Polymer modification matrix in pharmaceutical hot melt extrusion

- Track 14-5Polymer extraction and modelling

- Track 14-6Polymer extraction and modelling

- Track 14-7Modelling of heat transfer through a nanocellular polymer foam

- Track 14-8Modelling of silk-reinforced PDMS

Tissue engineering is the immense area of research in recent years because of its vast potential in the repair or replacement of impaired tissues and organs. The present research will focus on scaffolds as they are one of the three most important factors, including seed cells, growth hormones and scaffolds in tissue engineering. Among the polymers used in tissue engineering, polyhydroxy esters (such as PLA, PGA, and PLGA) have extensive attention for a variety of biomedical applications. Besides, PCL has been widely used as a tissue engineering scaffold. Scaffolds have been used for tissue engineering such as bone, cartilage, ligament, skin, vascular tissues, neural tissues, and skeletal muscle and as vehicle for the delivery of drugs, proteins, and DNA. The worldwide market for tissue engineering and regeneration products is expected to reach USD 11.5 billion by 2022.

- Track 15-1Tissue engineering and Regenerative medicine

- Track 15-2Whole organ engineering and approaches

- Track 15-3Bone and cartilage tissue engineering

- Track 15-4Scaffolds

- Track 15-5Novel approaches in guided tissue regeneration

- Track 15-6Biopolymer methods in Cancer therapy

- Track 15-7Crosslinking Biopolymers for Advanced Drug Delivery

- Track 15-8Encapsulation vs. Polymer Therapeutics

- Track 15-9Chitosan-Polyvinyl Alcohol-Ampicillin

- Track 15-10Nanopharmaceuticals and nanomedicine

- Track 15-11Polyamidoamine Nanoparticles for oral drug administration

- Track 15-12Nanodelivery systems

In modern times, a new class of biocompatible polymers and therapeutic polymeric systems and materials are being researched and have shown good amount of attraction for areas in polymer science. Attention towards polymeric compounds that can be bioassimilated is increased, primarily in the field of time-limited therapeutic applications. Among all the new candidates for materials that can be used to implant within the body, only a handful exhibit all the necessary properties required for safe functioning within the human body. Many researchers are turning towards synthesizing novel artificial polymeric materials or biopolymers, i.e. polymers of non-natural origin that are composed of pro-metabolite building blocks which can be utilized as components of biomedical or pharmacological therapeutic systems.

- Track 16-1Polymer-based photovoltaic devices

- Track 16-2Polymer blend electrolyte

- Track 16-3Polymer hydrogel materials for fuel cells

- Track 16-4Hybrid polymer-inorganic composites

- Track 16-5Polymer composites for energy storage applications

- Track 16-6Polymer membranes in energy applications

- Track 16-7Polymer-based organic batteries

- Track 16-8Optical and electrochemical characterizations of polymers

- Track 16-9Electrochemiluminescent immunoassay for diclofenac using conductive polymer

- Track 16-10Bioartificial Polymeric System

- Track 16-11Biopolymers for diabetic wound healing management.

- Track 16-12PHA synthesis in flax on plant mechanical properties

- Track 16-13Chitosan-based film production for food technology

- Track 16-14Polymers for Electronics, Energy, Sensors and Environmental Applications

- Track 16-15Biomedical & Environmental Applications

- Track 16-16Applications in Packing

Cellulose the most generous natural biopolymer on the earth, synthesized by plants, algae and also some species of bacteria and microorganisms. The Plant derivative cellulose and Black Carbon (BC) have the same chemical composition but differ in structure and physical properties. The BC network structure comprises cellulose Nano fibrils 3-8 nm in diameter, and the crystalline regions are been the normal cellulose I. The properties such as the Nano metric structure, unique physical and mechanical properties together produce higher purity that lead to great number of commercial products. Lignocellulosic agricultural byproducts are an extensive and cheap source for cellulose fibers. Agro-based Biofibers have the architecture, properties and design that make them suitable for use as composite, textile, pulp and paper manufacture. In addition, Biofibers can be used to produce biofuel, chemicals, enzymes and food. The global bio-fiber composites market reached $ 3.8 billion in 2016, with CAGR of 10% in last three years. Among them, the automotive and construction industry were the greater application segments. By 2023, this natural fiber composite market is expected to reach $7.6 billion (7.9% CAGR).

- Track 17-1Lightweight materials from Biofibers & Biopolymers

- Track 17-2Biopolymers from Gluconacetobacter xylinus

- Track 17-3Biofiber Reinforcements in composite materials of Biopolymers

- Track 17-4Microbial production of Biopolymers

Biodegradable polymers are a specific type of polymer that breaks down after its intended purpose to result in natural by-products such as gases (CO2, N2), water, biomass, and inorganic salts. These are found both naturally and synthetically made, and largely consist of ester, amide, and ether functional groups. Their properties and breakdown mechanism are determined by their exact structure. These polymers are often synthesized by condensation reactions, ring opening polymerization, and metal catalysts. There are vast examples and applications of biodegradable polymers.

- Track 18-1Advanced Biodegradable polymers

- Track 18-2Biodegradable polymers for Industrial Applications

- Track 18-3Biodegradable polymer applications

- Track 18-4General Biodegradable polymer applications

In the field of Polymer science and nanotechnology, Nano polymers and nanoclays have gained massive interests from researchers and in recent literatures. Nanotechnology is included in the most popular areas for today’s research and development and basically in all areas of technical disciplines. This also includes polymer science, which includes an wide range of sub-fields. Nanopolymers are used in microelectronics and the micro-devices are now below 100 nm. Both Nanopolymers and Polymer based Biomaterials are used for drug delivery, miniemulsion particles, fuel cell electrode polymer bound catalysts, polymer films, inprint lithography, electrospun nanofibers and polymer blends. Nanopolymers include various physical properties that are applied in composite reinforcement for imparting abilities to the composite such as barrier strength, electro-optical properties, flame resistance. Recent enthusiasm in polymer matrix based nanocomposites was emerged initially with interesting observations involving exfoliated clay and more recent studies with carbon nanotubes, carbon nanofibers, exfoliated graphite (graphene), nanocrystalline metals and a host of additional nanoscale inorganic filler or fiber modifications.

- Track 19-1Membrane Based on Ti(IV) Functionalized Nanopolymers

- Track 19-2Structural bioinformatics

- Track 19-3Graphene incorportated polymers

- Track 19-4Carbon Nanotubes from Biodegradable Poly-lactic Films

- Track 19-5Polymeric Nanoparticles

- Track 19-6multifunctional textile cotton fabrics with polyvinyl acetate metal nanocomposite

- Track 19-7Nanomedicine made of cyanoacrylate polymer

- Track 19-8Biocompatible nanopolymers and treatment of cancer

- Track 19-9conductive nanopolymers and polymer electronics

- Track 19-10functionalized soluble nanopolymers

- Track 19-11Polymer nanocarriers

- Track 19-12bio-nanocomposite hydrogel beads

- Track 19-13Polycaprolactone electrospun nano fibers

- Track 19-14Nanobiopolymers Fabrication

- Track 19-15Smart Polymersomes

- Track 19-16Hybrid Solid Polymer Electrolytes

- Track 19-17Nonfullerene Polymer Solar Cells

- Track 19-18Lanthanide-based supramolecular polymers

- Track 19-19Polyethersulfone/Epoxy Composites

- Track 19-20Biomedical Applications of PAMAM Dendrimers

- Track 19-21Shape Memory Polymers

- Track 19-22Nanosystems Formed by Degradable Antibacterial Poly(Aspartic Acid)

- Track 19-23Monochromophore-Based Polymer