Alexey Nazarov

MSTU “STANKINâ€, Russia

Title: Design of the SLS-machine for PEEK

Submitted Date: 13-04-2018

Biography

Alexey Nazarov is the designer of SLS/SLM equipment, engineer of the Laboratory of Innovative Additive Technologies of MSTU \"STANKIN\", Moscow.

Abstract

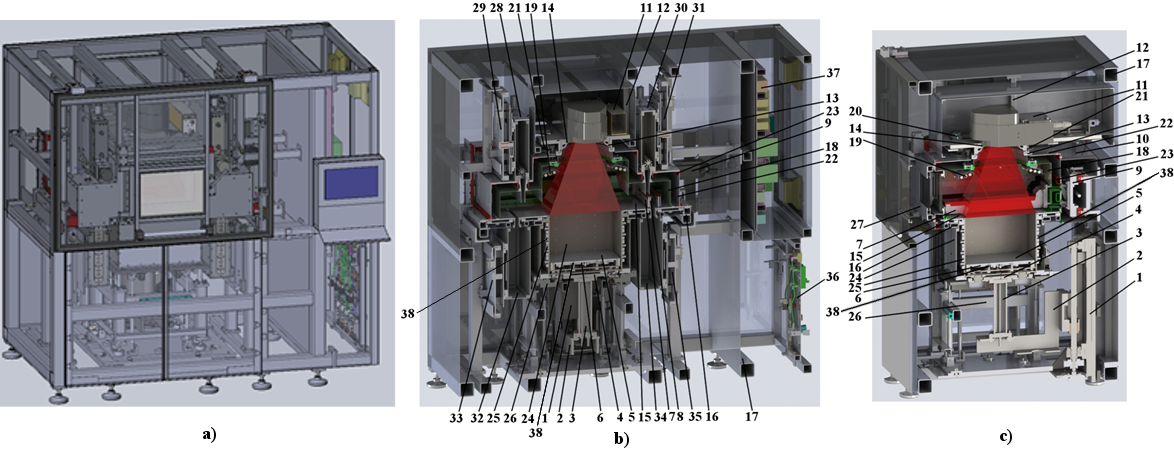

Very interesting are the parts manufactured by the selective laser sintering (SLS) technology from some types of powders\r\nbased on polyetheretherketone (PEEK). They have high strength values of up to 95 MPa (vs. 45 MPa for conventional\r\npolyamides) and Young’s modulus of up to 4400 MPa (vs. 1500 MPa for conventional polyamides), have high heat resistance\r\n(maintenance of physical and mechanical properties during short-term exposure to temperatures up to 310 °C and long-term\r\nexposure to temperatures of 260°C), as well as excellent biocompatibility and insulating (dielectric) properties. A set of these\r\nproperties in combination with the capabilities of the SLS method allows creating unique parts. These parts are increasingly\r\nused in the aerospace industry, medicine, and motorsport. We present the original design of the SLS facility (hereinafter\r\nreferred to as SLS-machine), which uses PEEK. The SLS machine includes the following main units, systems and parts (Fig. 1):\r\n1-lower transition table vertical drive, 2-lower transition table bracket; 3-lower transition table cooled rod; 4-lower transition\r\ntable (has the ability to automatically engage with and disengage from the building platform); 5-building platform; 6-building\r\nplatform heating system; 7-recoater; 8-double knife; 9-recoater drive; 10-airtight casing of recoater; 11-laser-optical unit;\r\n12-laser-optical unit frame; 13-ring of laser-optical unit; 14-ZnSe-glass; 15-powder depositing main plate; 16-main plate\r\nframe; 17-main frame of the SLS machine; 18-airtight inner chamber; 19-top heaters; 20-pyrometer; 21-illumination lamp;\r\n22-protective external chamber; 23-external chamber frame; 24-changeable frame; 25-changeable frame heating system;\r\n26-changeable frame clamping device; 27-double-protective door; 28-left powder delivery hopper; 29-left powder delivery\r\nhopper clamping device; 30-right powder delivery hopper; 31-right powder delivery hopper clamping device; 32-left powder\r\ncollection hopper; 33-left powder collection hopper clamping device; 34-right powder collection hopper; 35-right powder\r\ncollection hopper clamping device; 36-air-gas system; 37-electric control device; 38-thermocouple.\r\nFigure 1: Design of the SLS machine (described in the text): a-general view, b-longitudinal section (axonometry), c-cross-section (axonometry)

Cesar Cunha

University of Madeira, Portugal

Title: From invisible marine exopolymers to heteroâ€aggregates: Plastics sinking?

Submitted Date: 27-06-2018

Biography

Nereida Cordeiro is an Associated Professor of Chemistry in the Faculty of Sciences and Engineering of the University of Madeira. She holds a degree in Analytical\r\nChemistry (University of Aveiro) and PhD in Chemistry (University of Aveiro). Her main research interests are in Analytical and Environmental Chemistry, with focus\r\non biomaterials and biotechnology. She authored more than 70 scientific publications in international journals.\r\nncordeiro@staff.uma.pt

Abstract

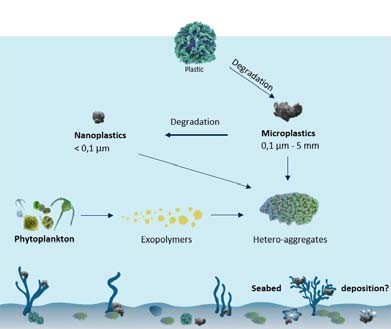

Human consumerism gave rise to a sea filled with plastic debris resistant to degradation, and with increasing\r\naccumulation in the marine environment. Nano (0.1 μm) and microâ€plastics (0.1 μm †0.5 mm) are of particular\r\nconcern because they can be eaten by marine life and enter the food chain. Plastics particles have been found\r\nthroughout the ocean, from the surface to sediment on the seabed. However, plastic concentrations at the surface of the\r\nocean were lower than expected, leading to think on a deposition of plastics from the surface to deeper layers of the\r\nocean. To understand the plastics particles bioavailability to marine organisms as well as their fate in the water column,\r\nit is essential to investigate their interactions with phytoplankton. Microalgae display sticky substances that can form\r\naggregates which can retain plastic particles. This work was focused to answer the question: Does the phytoplankton\r\naggregate plastics and transport them to the seabed? Thus, the microalgae potential to form heteroâ€aggregates with\r\nplastic particles, was studied. Factors as the microalgae species, and their physiological status, the plastic particles type and\r\nsize, were also analysed. Microalgae were exposed to nano and microâ€plastics during their growth culture cycles and\r\nheteroâ€aggregates (a gelâ€like structure) constituted of microalgae, microplastics and exopolymers were formed. The\r\neffects of nano and microâ€plastics were determined on microalgal physiology in terms of growth and chlorophyll fluorescence.\r\nThe heteroâ€aggregate pores structure, composition and the density were determined. Overall, the results highlight the\r\npotential of the exopolymers to interact with plastic particles, and the heteroâ€aggregates importance for the plastics vertical\r\ntransport from the water surface to the sediment.